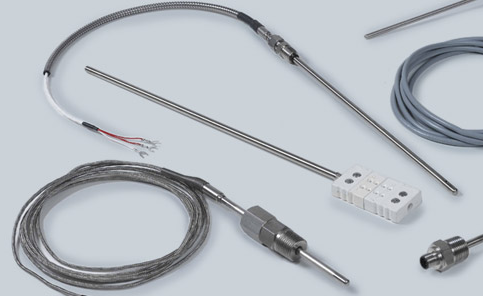

FAQ - Resistance Temperature Sensors (RTD), including Pt100 and Pt1000 temperature sensors

FAQ - Resistance Temperature Sensors (RTD), including Pt100 and Pt1000 temperature sensors

Q - What does RTD stand for?

A - RTD stands for resistance temperature sensor, but is also called PRT (platinum resistance temperature sensor)

Q - What is RTD?

A - A temperature sensor that contains a resistor (typically 100 or 1000 ohms). Resistance changes with temperature; It can then be correlated to provide a temperature reading. RTD is considered one of the most accurate temperature sensors. In addition to providing very good accuracy, they also provide excellent stability, repeatability and high immunity to electrical noise. This means that RTD sensors are well suited for applications in process and industrial automation environments, especially around motors, generators, and other high-voltage equipment.

Q - What is PRT?

A - Platinum resistance temperature sensor (PRT) is an RTD that uses platinum as the sensing element. The most common PRTs are Pt100, Pt500, and Pt1000. (PRT is just a more specific name for RTD)

Q - I need a new RTD sensor, but I don't know what type I have been using. Can you help me?

A - The first step to identify an RTD is to find out how many wires (2, 3 or 4) it has. Then you can connect the RTD to a multimeter. If it is a pt100, it should read between 107 and 110 Ω at room temperature However, if it is pt1000, you should get a reading of 1007 - 1100 Ω, which confirms that it is Pt1000.

Please note that these readings are standard readings for new RTD sensors. If the sensor is damaged or used continuously, your readings may be different

Q - What is accuracy class A or B?

A - The resistance and temperature characteristics of RTDs are defined in the international standard IEC 60751:2008. In this standard, there are precision standards to provide good interchangeability. Class A and B are two precision standards. We provide tolerance reference table

Q - What is the difference between RTD and Pt100?

A - We are often asked this question, but Pt100s and Pt1000s are two types of RTDs (Pt500 is another type of RTD, but it is outdated now)

Q - Do I need an extension cable for my RTD sensor?

A - RTDs use cables because they detect temperature by calculating the change in resistance in the material, so you can simply order RTDs with long leads, or purchase additional cables to extend themselves.

Q - How do I choose the right RTD sensor for my application?

A - When choosing RTD, you must consider the following points:

• What temperature do you measure (surface or immersed in solid, liquid or gas)?

• If you need a fast response time, please read our RTD technology page to learn about the various factors in choosing a response time.

• The specific dimensions required for your application, such as probe diameter, probe length, compression fitting, type of connector required, etc.

• Do you need specific jacket materials?

• Do you need to calibrate the sensor?

• Does the sensor need to be resistant to chemicals/wear/vibration or any other environmental factors?

• Is there a high EMF (electromagnetic interference) potential in the power switch, rectifier or radio wave?

• Any other installation precautions? (For example, whether the sensor needs to be bent before installation)

• Distance between sensing area and instrument

• Temperature in the sensing environment over the entire length of the sensor

• Connection preferences

• The current wiring configuration, such as a 4-wire sensor, will not be compatible with a 3-wire configuration

If you want to know more, please call or email 18717811268 sales@weilianchina.com