Thermocouple FAQ Summary

Thermocouple FAQ Summary

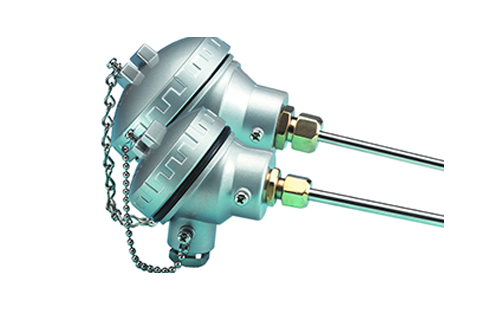

Q - What are thermocouples?

A - Thermocouple is a temperature sensor used to measure temperature in many processes. The thermocouple consists of two wire legs made of different metals, one end of which is fixed together to form a connection point. When the junction experiences temperature changes, a voltage will be generated, and then the voltage can be measured and used as a reference for temperature. We provide many types of thermocouples for various applications. To discuss which is most suitable for your application, please contact us here.

Q - I need a new thermocouple, but I don't know what type I have been using. Can you help me?

Answer - The easiest way to identify thermocouples is through the color of the wire (see our thermocouple wire diagram). For more complex temperature sensors, please send a few photos together with any other information to“ sales@weilianchina.com ”We will reply to you within one working day.

Q - What are mineral insulated thermocouple cables and their advantages?

A - The mineral insulated thermocouple cable is composed of an external metal sheath to contain the thermocouple conductor; The sheath shall then be filled with highly compacted magnesium oxide powder to prevent conductor contact at any point other than the fixed connection point. This construction allows the jacket to be easily bent or shaped to the shape required by the user, but remains rigid during use. The entire assembly is sealed, providing the conductor with full protection from the operating environment.

Mineral insulated thermocouples have a wide temperature range, which are solid and flexible, and can be made into long lengths and wide diameter ranges. They also have very fast response times and are generally more resistant to chemicals because of the jacket and insulated power supply that protect them, which means they have a longer service life than ordinary temperature sensors.

Q - What is the difference between thermocouples and RTDs?

A - We have a detailed case study that provides practical advice and comparison on the differences between thermocouples and RTD temperature sensors: differences between thermocouples and RTDs http://www.weilianchina.com/news/wl164.html

Q - What is a K-type thermocouple?

A - K thermocouple is the most popular thermocouple, which can be used in a wide range of applications. It has a good output mV per degree Celsius and a wide operating temperature range (typically – 200 to+1200 C). It is made of two conductors. The positive electrode is 90% nickel, 10% chromium, and the negative electrode is 95% nickel, 2% aluminum, 2% manganese, and 1% silicon.

Which Q - K leg is magnetic?

A - K thermocouples have two legs (Alumel and Chromel). Alumel legs are magnetic, while Chromel legs are nonmagnetic. This helps identify thermocouples when there is no color coding.

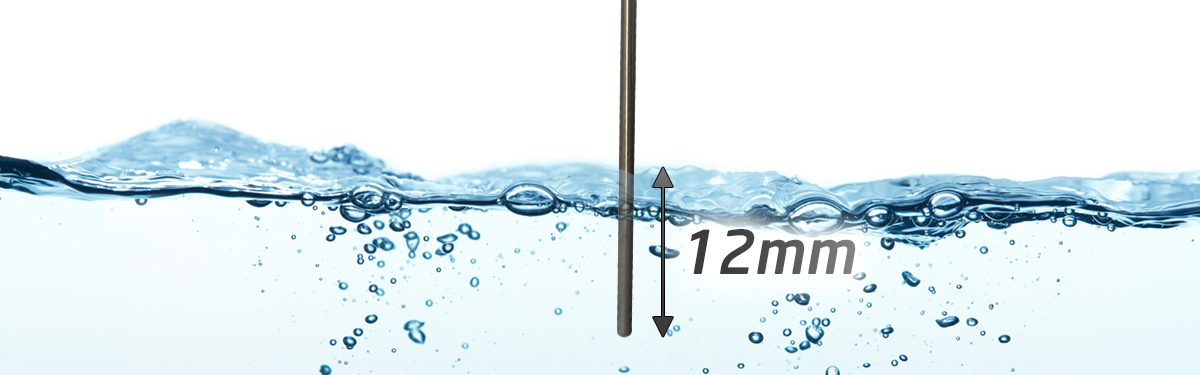

Q - How long should my thermocouple be immersed in the application?

A - Thermocouple temperature sensors are "tip" sensing devices, which makes them ideal for surface and immersion applications (depending on the temperature sensor type). Immersion thermocouples must be used with care to avoid rod conduction errors, which can cause erroneous readings when heat flows into or out of the jacket and during the flow in or out process. As a rule of thumb, the temperature sensor should be immersed at least 4 times the outer diameter of the sheath (for example, if the diameter is 3 mm, the minimum immersion depth is 12 mm)

Q – How accurate are thermocouples?

A - There are many types of thermocouples (K, T, J, E, N, R, S, and B). Each type has its own accuracy according to IEC. Each type of thermocouple usually has 3 accuracy tolerances, and Level 1 is the most accurate. For K-type thermocouples, accuracy class 1 is 1.5 ° C or 0.4% of reading, whichever is greater. We provide a complete accuracy chart of all thermocouples here for reference at www.weilianchina.com

Q - What is the difference between thermocouple grade cables and expansion grade cables?

A - Thermocouple grade cables are used inside the temperature sensor to create sensing points, and extension cables are used to connect the temperature sensor to the measuring instrument. It is actually the same as thermocouple grade cable, which means that the chance of error is greatly reduced. Based on past experience, we recommend using a distance of no more than 80 - 100 meters, as this will start to cause reading errors, and we also recommend using shielded cables for longer cables.

Q - What is a thermocouple compensation cable?

A - Compensation cable is an economical alternative to extension cable because it uses cheaper alloys, which are different from thermocouple grade alloys, but have the same output in a limited temperature range. The thermocouple and extension cable can be interchanged, but the compensation cable can only be used for its intended purpose (that is, the compensation cable cannot be used to establish a connection inside the temperature sensor). For more detailed technical information on compensating cables, please visit our thermocouple technology page.

Q - How do I choose the right thermocouple for my application?

A - When selecting thermocouples, the following points must be considered:

• What temperature do you measure (surface or immersed in solid, liquid or gas)?

• The temperature range you need to measure (as a general rule, your working temperature should not be at the higher end of the thermocouple temperature range, because its depreciation speed will be much faster than it should be, for example, your working temperature varies from 650 ° to 690 ° C, instead of selecting J type thermocouple (rated+20 to+700 ° C), you should choose the second higher E type thermocouple (rated 0 to+800 ° C)

• If quick response time is required, please find out the various factors for selecting response time on our thermocouple technology page.

• The specific dimensions required for your application, such as probe diameter, probe length, compression fitting, type of connector required, etc.

• Do you need specific jacket materials?

• Do you need to calibrate the temperature sensor?

• Does the temperature sensor need to be resistant to chemicals/abrasion/vibration or any other environmental factors?

• Is there a high EMF (electromagnetic interference) potential in the power switch, rectifier or radio wave?

• Any other installation precautions? (For example, whether the temperature sensor needs to be bent before installation)