Winding wire or film resistance temperature sensor: which is better?

Winding wire or film resistance temperature sensor: which is better?

Many process applications rely on wound wire or thin film resistance temperature detectors (RTDs) to provide efficient and safe operation. These two types of resistance thermometers have different characteristics, and each has its advantages and disadvantages. In fact, this is a comparison between apples and oranges. What is more puzzling is that European standards take differences into account, while American standards treat them equally.

Which is better, wire wound or film resistance temperature detector (RTD)? The answer depends on several variables, especially your process environment. Adding to the confusion are different standards, IEC and ASTM.

To find out which industrial resistance thermometer is more suitable for your application, it is helpful to understand the composition of each sensor and their advantages and disadvantages in detail.

Difference between wound resistor and film resistor

An older technology, wire wound resistors consist of a thin platinum wire wrapped and fused in a glass case or embedded in ceramics. The glass wound resistor can withstand a certain degree of vibration, but when the temperature is higher than+400 ° C (+752 ° F), its accuracy will be reduced when the glass characteristics begin to change. This change increases conductivity and causes the sensor to lose accuracy. On the other hand, ceramic wire wound resistors have small drift due to mechanical force during temperature change, but they are easy to be damaged under vibration.

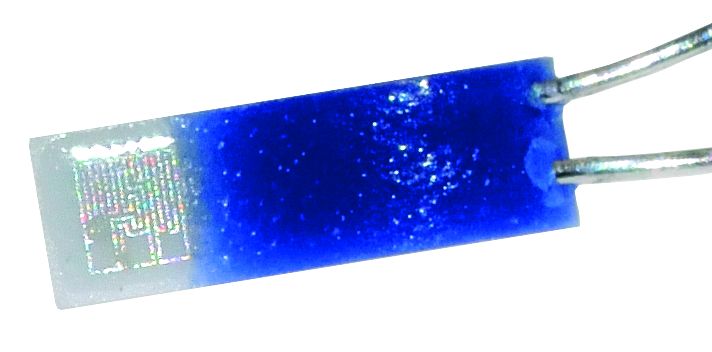

Thin film thermal resistance

In thin film resistors, a very thin layer of platinum is deposited on a ceramic carrier. Then the platinum film and the wire connection are sealed together with a glass layer. The disadvantage of using this type of RTD is that the performance of platinum film, ceramic matrix and glass layer is different at different temperatures. When the temperature is too low (- 50 ° C/- 58 ° F) or too high (+500 ° C/+932 ° F), measurements made with film resistors may deviate from the actual value by more than the actual value. A wound resistor. This deviation has nothing to do with the quality and process of materials, but is the result of the design and the type of materials used, which has been resolved in the IEC standard.

On the plus side, thin film resistors are small in size and vibration resistant due to their small mass (weight) and structure. They are also more sensitive. In addition, since this type of RTD uses only a very small amount of platinum, and the precious metal of wire wound resistor is very long, the thin film resistance thermometer is cheaper.

IEC 60751 and ASTM E1137/E1137M

Due to its large size, high price and sensitivity to vibration, the wire wound detector is falling out of favor and being replaced by the film sensor. The IEC 60751 (DIN EN 60751) industrial platinum resistance thermometer and platinum temperature sensor standard was revised in 2008 to take into account the difference between winding resistance and film resistance. It lists the tolerance classes and temperature ranges respectively (Table 1). With this standard, there is no room for misunderstanding, because it clearly defines the accuracy level of each type of resistance temperature detector.

Effective temperature range | Tolerance value* | ||

Winding resistance | Film resistance | ||

AA | −50… +250°C | 0…+150°C | ±(0.1 + 0.00017 |t|) |

one kind | −100…+450°C | −30… +300°C | ±(0.15 + 0.002 |t|) |

B | −196…+600°C | −50… +500°C | ±(0.3 + 0.005 |t|) |

C | -196…+600°C | −50… +600°C | ±(0.6 + 0.01 |t|) |

*|t| = with°C Temperature module in units, regardless of symbols | |||

Table 1: IEC 60751 Thermometer Standards Using Wound Wire and Thin Film Resistors

The ASTM E1137/E1137M standard was reviewed again in 2014, but was not revised to include differences in the behavior of wound wires and thin film resistors. The standard continues to operate in two tolerance classes (A and B), both defined as a temperature range of - 200 ° C to+650 ° C, regardless of the type of sensor.

Comparison of apples and oranges

When evaluating two different types of thermometers side by side, the different standards used in IEC 60751 and ASTM E1137/E1137M may cause confusion. In fact, this is a comparison between apples and oranges. At first glance, detectors conforming to ASTM standards seem to be better than detectors conforming to IEC standards, because the former covers a wider temperature range. However, ASTM standards do not consider how differences in material behavior affect accuracy, especially at low and high temperatures (Table 2).

ASTM E1137/E1137M | IEC 60751:2008 | ||||||

No information | Winding resistance | Film resistor | |||||

Grade A | Grade B | Grade AA | Grade A | Grade B | Grade AA | Grade A | Grade B |

−200 +650 | −200 +650 | −50 +250 | −100 +450 | −196 +600 | 0 +150 | −30 +300 | −50 +500 |

Table 2: Temperature ranges (in ° C) and tolerance classes/grades of wire wound and film thermometers in accordance with ASTM E1137/E1137M and IEC 60751

Advantages and disadvantages of each RTD type

The process conditions determine which type of industrial resistance thermometer is more suitable for application, because each has its advantages and disadvantages.

Advantages of Wirewound Resistors

●High precision in the whole temperature range, which is required in some laboratory settings or trade handover applications

Disadvantages of winding resistance

●No vibration resistance

●Larger length (approx. 25 mm)

●10 times more expensive than film resistor

Advantages of Thin Film Resistors

●Compact length (approx. 3 mm)

●Vibration resistance, due to their smaller mass and no moving parts, makes them ideal for compressor and bearing applications

●Structure of tip sensitive sensor

●About 1/10 of the cost of wire wound resistors

Disadvantages of film resistance

●Loss of accuracy at low and high temperatures

In conclusion, if you need to use high-precision RTDs in a wide temperature range, especially in a higher temperature range, the higher cost of wire wound resistors is worth it.

On the other hand, the film resistance thermometer is very suitable for food and beverage, pharmaceutical and other sanitary applications, where the typical process temperature is kept below+250 ° C. VILIAN TR21 series micro RTD adopts the latest film technology, which is an economical and space saving solution for liquid and gas medium temperature measurement. Each resistance thermometer has a direct sensor output (Pt100/Pt1000 for 3-wire or 4-wire versions) or an integrated transmitter with a 4... 20mA output signal. All process connections meet the strict requirements of sanitary applications. Electrical components are protected against moisture. The insertion length, process connection, sensor and connection method can be selected according to your needs.

With its low cost and other advantages, thin film sensors are increasingly popular in many, though not all, applications. The team of temperature experts who are still not sure what kind of industrial RTD maintenance to use in your specific situation would be happy to provide further assistance. Tel./WeChat 18717811268 Huang Gong sales@weilianchina.com