Grain Growth in K-type Thermocouple Temperature Sensors: Some Causes and Solutions

Grain Growth in K-type Thermocouple Temperature Sensors: Some Causes and Solutions

Over time, extremely high temperatures can cause grain growth in K-type thermocouples, leading to metal separation and thermocouple failure. Fortunately, there are good solutions to minimize the effects of grain growth.

Grain growth is a common cause of failure of K-type thermocouples. In applications such as tube skin temperature measurement in combustion process furnaces, the temperature measurement equipment is exposed to process gas and radiant energy, and the temperature generated is much higher than the tube skin temperature measurement node. The temperature rise is the primary factor of grain growth over time, which will eventually damage the thermocouple.

Causes and effects of grain growth

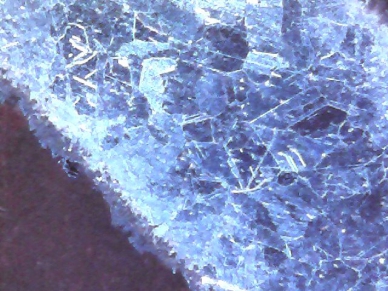

Examples of metallic crystal structures

Examples of metallic crystal structures

Grain growth is the condition of microcrystalline or grain enlargement of materials. In thermocouples, it is a failure mode, which is related to the grain structure of the metal, different expansion coefficients and the high temperature of the application - type K is higher than 649 ° C.

Sheathed thermocouples consist of three different types of metals: one in the positive conductor, one in the negative conductor, and one in the sheath. The sheath is usually made of stainless steel or other alloys, and each type of thermocouple has a specific pair of metal conductors. Type K is the most commonly used thermocouple, with a NiCr (Chromel ®) Positive pole and a NiAl (Alumel ®) negative pole.

Each metal has a different coefficient of expansion - stainless steel has the largest negative leg and the smallest. Therefore, each time the K-type thermocouple is exposed to high temperature, the negative conductor leg will bear pressure. The crystal structure of NiAl varies from many small grains (processing or manufacturing state) to a few large grains (relaxation state). The large crystal structure has less mechanical "roughness" and less "wall frame". When subjected to different expansion pressures, the negative conductor is actually separated. Small conductors are also more susceptible to grain growth than large conductors.

Grain growth and failure in K-type thermocouples have been well proven. In one test, the 310 stainless steel sheathed K-type thermocouple with an outer diameter of 6mm was subjected to a temperature between 1093 ° C and 1149 ° C. Over time, all samples showed extensive grain growth of 2 to 5 grains on the cross-section of the wire, although not all samples failed. Failure rate over time:

●Within three months 10%

●Within six months 60%

●Within 11 months 72%

How to reduce grain growth and minimize its impact

There are three main methods to reduce the grain growth of K-type thermocouple.

1 Sheath material:One method is to select a sheath material whose coefficient matches the coefficient of the conductor very well. Traditional sheaths are usually made of 310 stainless steel. The huge difference between the expansion coefficient of the sheath and the expansion coefficient of the wire leads to a high failure rate of the thermocouple in the above tests. If the expansion coefficients of conductor and sheath are the same, the grain growth will be significantly reduced or even completely eliminated.

The expansion coefficient of 600 is closer to that of the conductor. This alloy works well at high temperature, but can only be used in the environment without sulfur or other reducing agents, which will lead to chromium oxidation or "green rot".

I600 has been the preferred material to reduce grain growth for many years until new materials appear. Pyrosil ® D or Incotherm ® Alloy TD - they are the same product, but produced by different manufacturers - provides better protection against grain growth. The formula of this alloy contains less pollutants than stainless steel, and the expansion coefficient almost matches the conductor expansion of N-type thermocouple. In fact, for high-temperature furnace applications, it has become standard practice for major oil refining companies to use thermocouples wrapped in Pyrosil/Alloy TD.

2 Engineering cable:Since smaller conductors are more susceptible to grain growth than larger conductors, "engineering cables" can solve this problem. The maintenance uses non-standard MI (mineral insulated) cables designed according to our specifications. The negative leg is made bigger, which makes it more resistant to the separation of grain growth.

3 Thermocouple placement:For the flame process furnace, keeping the thermocouple sheath in contact with the furnace tube and using the tube as the radiator are two methods to keep the thermocouple much lower than the ambient gas temperature, thus extending the service life of the thermocouple and reducing the failure rate of the thermocouple service life.

As long as K-type thermocouple is repeatedly exposed to extremely high temperature, grain growth may occur. However, due to newer and better metallurgical and engineering technologies, grain growth is no longer a major threat in the past. The temperature measurement experts of Villian understand the unique requirements of furnace skin thermocouples and refineries. Contact us to find out which thermocouple types and components are best suited for your application. Tel./WeChat 18717811268 Huang Gong sales@weilianchina.com