Temperature measurement test questions

Temperature measurement test questions

Questions and answers of RTD temperature sensor

RTD(Resistance temperature detector)

Acronym for resistance temperature detector or equipment. The working principle of the resistance temperature detector is that the resistance in the wire changes with the temperature.

Thermal resistance element

The sensing part of RTD temperature sensor is most commonly made of platinum, nickel or copper. RTD has two types of elements: wound wire and film.

Thermal resistance probe

An assembly consisting of elements, sheaths, leads, and terminals or connections. The standard RTD probe is made of 100 ohm platinum European curve element (alpha=0.00385).

Platinum thermistor

Platinum RTDs, also known as Pt RTDs, are generally the most linear, stable, repeatable and accurate of all RTD temperature sensors. The platinum wire was selected because it can best meet the needs of precise temperature measurement.

Thin film thermal resistance

The thin-film RTD temperature sensor consists of a thin layer of base metal embedded in a ceramic substrate and is trimmed to produce the required resistance value.

The fabrication method of RTD temperature sensor is to deposit platinum as a thin film on the substrate, and then package them. This approach allows the production of small, fast response, accurate sensors.

The membrane element complies with the European curve/DIN 43760 standard and the "0.1% DIN" standard tolerance.

Class A thermal resistance

Highest RTD element tolerance and accuracy, Class A (IEC-751), Alpha=0.00385

Type B thermal resistance

Tolerance and accuracy of the most common RTD elements, Class B (IEC-751), Alpha=0.00385

Alpha. 00385 curve

European curve conforms to "0.1% DIN" standard tolerance and DIN 43760 standard

sheath

The sheath, a closed end tube, and a fixed element protect it from moisture and the environment to be tested. The jacket also provides protection and stability for transition leads of fragile component lines.

The standard sheath of RTD temperature sensor is 3 mm (1/8 inch) and 6 mm (1/4 inch) outer diameter 304 stainless steel pipe. Other OD and materials can be provided upon request.

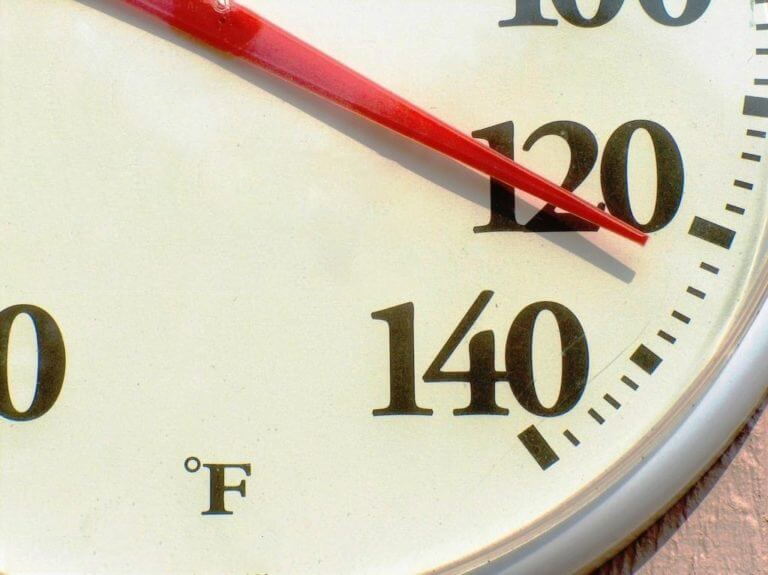

What is the approximate bearing high temperature alarm and shutdown setting?

High speed bearing has high temperature protection. High temperature alarm and shutdown instruments are generally set at 95 ℃ and 105 ℃ (see the station diagram for specific settings/parameters).

What type of primary element is used to measure compressor bearing temperature? Take the device name as an example.

In the lower temperature range, "RTD" (resistance temperature detector) is superior to thermocouple.

On finishing gas compressor: PT 100-RTD is used to measure the temperature of journal and thrust bearing.

On the solar gas compressor: "k" type thermocouple is used to measure the temperature of journal and thrust bearing.

If the compressor bearing temperature rises, what may be the cause?

The following are possible conditions of compressor bearing temperature rise:

Poor bearing

Low lubricating oil supply pressure

Aging lubricating oil

Excessive compressor load

Dirty lubricating oil cooler

Lube oil cooler fan running at low speed

The thermostatic valve in the pipeline from lubricating oil to cooler is defective

Which of the two "resistance and thermocouple" is recommended to measure the bearing temperature?

Resistance Temperature Detector – RTD is superior to thermocouple in measuring bearing temperature.

RTD temperature sensor is more accurate and linear when measuring the temperature in the range of - 200 ℃ to+200 ℃.

What are the manufacturer names of bearing thermometer?

We use the following manufacturing instruments to measure the bearing temperature:

DYMAC, Shanghai No. 3 Automation Instrument Factory, Shanghai Weilian (Fengran) Electronics, etc