FAQ of RTD temperature sensor

FAQ of RTD temperature sensor

Why is it recommended to use Pt100 Class A (according to IEC 60751) with a 4-wire connection?

Only the 4-wire connection completely compensates the line resistance effect of the entire cable circuit. For 2-wire or 3-wire connections, it may be possible to manually program the measured cable resistance as a transmitter parameter to correct the final reading.

But even in these cases, the parameters are correct only at the ambient temperature when measuring the cable. If the ambient temperature changes, the measuring circuit will lose its accuracy.

The 4-wire connection also compensates for ambient temperature changes.

Type A Pt100 RTDs are used for accurate temperature measurements, which is why wiring should always be done with 4 wires.

2. What is the difference between a 3 - or 4-wire configuration?

RTDs (Resistance Temperature Detectors) are available in 2, 3, or 4 lead configurations.

The best configuration for a particular application depends on many factors, but the sensor configuration must match the instrument, otherwise the lead wire resistance cancellation circuit may not work.

Factors to consider:

●Installation cost——More wires usually mean higher costs

●Free space——More or larger wires require more space

●Accuracy requirements– The 2-wire configuration can provide the required accuracy, especially for high resistance components

A. 2-lead RTD structure

A 2-wire RTD causes the lead resistance to increase to the element resistance. Therefore, the temperature reading is artificially high.

B. 3-lead RTD structure

只有当仪器可以测量真正的 3 线电阻时,3 线 RTD才能消除引线电阻误差。

当所有引线具有相同的电阻时,引线电阻误差消除最有效。使用相同 AWG、长度和成分的 3 根导线通常会导致引线电阻匹配在 5% 以内。

C. 4 引线 RTD 结构

A 4-wire RTD will cause resistance elimination only if the instrument can measure true 4-wire resistance.

Even if the AWG, length and/or composition of all 4 wires are different, the real 4-wire resistance measurement can effectively eliminate the lead resistance error.

D. Are any RTD configurations interchangeable?

● A 4-lead RTD can usually be used as a 3-lead RTD by eliminating (or tying) one of the leads

● 4-lead RTDs can be used as 2-lead RTDs by combining (shorting) common leads (usually with similar colors - white/white and red/red)

Warning: Combining common leads eliminates the benefits of lead resistance elimination

● 3-lead RTDs can be used as 2-lead RTDs by combining (short circuiting) common leads (usually with similar colors)

Warning: Combining common leads eliminates the benefits of lead resistance elimination

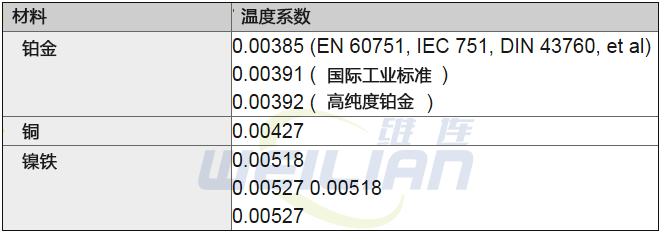

How do I know which type of alpha (TCR) curve to use?

CR (resistance temperature coefficient) is the normalized average resistance change of the sensing element in a specific temperature range (usually 0 to 100 ° C).

This value is independent of the base resistance and is a characteristic of the component material itself. The unit is ohm/ohm/C.

example:

The probe may read 100 ohms at 0 ° C, but at 100 ° C, the 0.00385 probe reads 138.5 ohms and the. 00392 probe reads 139.20 ohms.

A. The resistance curve depends on the instrument. Refer to your instrument manual for acceptable RTD temperature sensor (RTD) input types.

B. Common TCRs include:

When do we need the transmitter of RTD sensor?

There are no strict rules on when to designate a transmitter. Each temperature monitoring system has unique cost and accuracy requirements, as well as unique design problems to overcome.

Generally speaking, the transmitter has three advantages:

● Eliminate lead effects in temperature readings

● Output is less affected by electrical noise

● Adjust RTD signal

A. RTD lead effect:

The distance between the sensor and the control point is an obvious reason for specifying the transmitter.

Factors to consider:

● If the distance exceeds a few feet, the transmitter is more accurate than a 2-wire RTD

● In long distance, even 3-wire RTD cannot meet the required accuracy

● 4-wire RTD measuring circuit will effectively eliminate lead wire error, but the space and cost of additional two leads may exceed the cost of the transmitter

● High resistance sensing elements reduce the impact of lead resistance, but do not eliminate them

● RTD measuring circuits are usually low signal (1 mA or less) and prone to electrical noise - especially in long conductors.

● At a distance of more than 500 feet, the transmitter may be the only way to transmit RTD accuracy to the control electronics

B. Electrical noise:

Noise from motors, fluorescent lamps, or other sources reduces resistance or voltage signals, but has little effect on the controlled current of the transmitter.

Therefore, you may want to use the emitter at a relatively short distance in particularly noisy areas. The cost of the transmitter may even be lower than that of the specially shielded extension cord.

Simply twisting the transmitter cable pair is very effective for reducing noise; Shielded cables are not normally required.

C. Signal conditioning:

You may only need the transmitter for its signal conditioning circuit. RTD resistance/temperature curve is non-linear.

The transmitter changes the RTD resistance to industry standard 4-20 mA while linearizing the output to temperature. With the linear response of the transmitter, you do not need complex equations to interpret the readings.

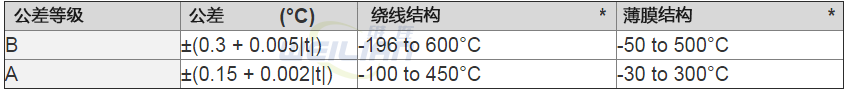

What are Categories A and B?

Platinum has become popular in the field of RTD (Resistance Temperature Detector). This is because its physical properties make it superior to other materials in sensing temperature.

To provide interchangeability between manufacturers for the global industry, some international standards have been adopted by most countries:

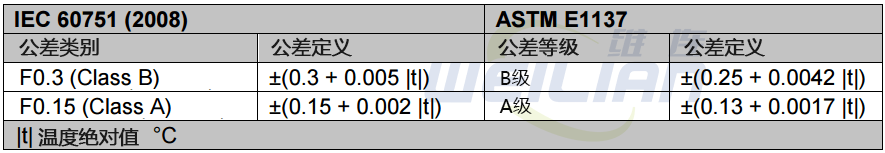

● IEC 60751 defines temperature accuracy and resistance/temperature characteristic curves for several tolerance classes

● "Class B" and "Class A" are the most common tolerance classes.

These are defined by a single nominal resistance/temperature characteristic curve and the following precision designations:

*Consult the sensor manufacturer for specific model sensor configurations

Many standards are copies or predecessors of IEC 60751. These include IEC 751, DIN 43760, EN 60751 and BS EN 60751.

The other standard, ASTM E1137, uses the same nominal characteristic curve, but has a different definition of tolerance, and specifies it as "Class B" and "Class A".

ASTM standards are not as widely used as IEC standards.

When do we need to use shielded leads (electrical noise) for RTDs?

Environments containing high voltage or electromagnetic fields (EMF) may require shielded leads.

These environments produce what is commonly called "noise" (EMI) in the sensing instrument. The leads act as antennas.

Two common techniques may help mitigate the effects of electrical noise:

● Twisting leads will help counteract induced noise.

● Leads may be covered by "shielding", usually silver plated copper braid (SPC braid). Grounding the shield of the instrument will only provide the best results.

What is the self heating constant?

The self heating constant defines the temperature rise in Kelvin per mW of applied power. The constant of each RTD element is measured under the standard conditions of 0 ℃ ice water.

Since the constant is measured under conditions that do not necessarily reflect the typical application environment, the self heating constant is mainly used to compare the self heating characteristics of one element with another.

In addition, the actual service conditions have a great influence on the self heating constant. For example, packaging components in thermal conductive materials will increase the surface area and thermal mass, thereby effectively reducing the self heating constant.

However, if the element is used in full or partial vacuum, the opposite will happen - the self heating constant will increase due to the decrease of the thermal conductivity of the surrounding medium.

In temperature sensing applications, excessive self heating will lead to significant measurement errors.

The dependence of self heating on thermal conductivity of surrounding medium can also be used to measure liquid level, flow, thermal conductivity, fluid density, etc.

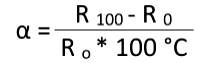

How is the temperature coefficient of platinum RTD element defined?

The temperature coefficient, also known as the "alpha value", is the average change in resistance between 0 and 100 ° C and is calculated using the formula

How are the resistance and temperature characteristics of platinum RTD components defined?

Callendar Van Dusen equation describes the relationship between resistance and temperature in platinum RTD elements.

For temperature t equal to or higher than 0 ℃, the equation is R (t)=R0 * (1+A * t+B * t ²)

For temperature t below 0 ℃, the formula is R (t)=R0 * (1+A * t+B * t ²+ C*(t-100°C)*t ³)

Where A, B, and C are constants of a particular RTD curve.

The constants of the IEC 60751 TC 3850ppm curve are:

A = 3.9083*10-3 ℃ -1

B = -5.775*10-7 ℃ -2

C = -4.183*10-12 ℃ -4

What is the difference between IEC 60751 and DIN EN 60751?

The IEC 60751 and DIN EN 60751 specifications are identical. The DIN specification is basically an IEC specification with a cover added.

What is the difference between IEC 60751 and ASTM E1137?

Both specifications apply to the standard 3850ppm temperature coefficient (0.385) platinum curve and are based on the ITS-90 temperature scale.

A major difference between the two specifications is the definition of tolerance classes, as follows

"F" indicates membrane element. If the tolerance of the winding component is defined, replace with "W".

The customer requires a temperature sensor assembly with platinum RTD elements in accordance with DIN 43760. Is this a valid specification for platinum RTD sensors?

DIN 43760 Sept 68 is suitable for 100 ohm nickel and platinum RTD elements.

The next edition of the specification DIN 43760 Sept 87 is only applicable to nickel and no longer applicable to platinum. DIN EN 60751 is a DIN specification for platinum RTD components