Introduction to RTD temperature sensor elements

Introduction to RTD temperature sensor elements

Resistance temperature detectors (RTDs) rely on predictable and repeatable phenomena of metal resistance changing with temperature.

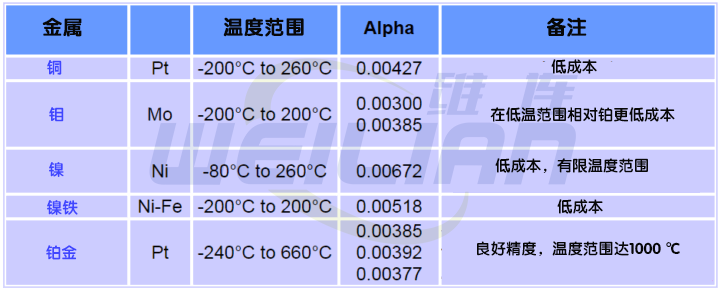

The temperature coefficients of all pure metals are in the same order of magnitude – 0.003 to 0.007 ohms/ohm/° C. The most common metals used for temperature sensing are platinum, nickel, copper, and molybdenum. Although the resistance temperature characteristics of some semiconductor and ceramic materials are used for temperature sensing, these sensors are not generally classified as RTD temperature sensors.

How are RTD temperature sensors built?

RTD temperature sensors can be manufactured in two ways: using wires or films. Wire RTD temperature sensor is a thin wire stretching coil placed in a ceramic tube to support and protect wire. You can use glazes to bond lines to ceramics. Wire types are generally more accurate due to tighter control of metal purity and fewer strain related errors. They are also more expensive.

The thin film RTD temperature sensor consists of a metal film that is screen printed or vacuum sputtered onto a ceramic or glass substrate. Then, the laser trimmer trims the RTD temperature sensor to the correct resistance value.

Thin film sensors are not as accurate as linear sensors, but they are relatively inexpensive, they are smaller and more robust. Thin film RTD temperature sensors can also be used as strain gauges - so do not strain them! Alumina elements shall be supported by grease or lightweight elastomers, but shall not be embedded in epoxy or mechanically clamped between hard surfaces.

RTDs cannot normally be used in the form of their basic sensing elements because they are too fragile. They are usually built into some type of component, which will enable them to withstand various environmental conditions that will be exposed when they are used. The most common is stainless steel pipe with thermal grease (which can also inhibit vibration). Standard pipe diameters include 3, 4.5, 6, 8, 10, 12 and 15 mm, and standard pipe lengths include 250, 300, 500, 750 and 1000 mm.

RTD characteristics

Metal RTDs have responses defined by polynomials:

R(t) = R 0 ( 1 + at + bt 2 + ct 3 )

Where R 0 is the resistance at 0 ° C, "t" is the temperature in Celsius, and "a", "b" and "c" are constants depending on metal properties. In practice, this equation is very close to most RTDs, but it is not perfect, so it usually needs to be modified slightly.

In general, the temperature characteristic of RTD is specified as a single number ("alpha"), which represents the average temperature coefficient in the temperature range of 0 to 100 ° C. The calculation formula is as follows:

Alpha=(R 100 – R 0)/100. R 0 ohm/ohm/° C

Note: RTD covers enough temperature range, so its response needs to be calibrated according to the latest temperature scale ITS90. For help with such calculations, refer to the RTD Temperature Calculator.

It should be noted that the temperature coefficients of alloys are usually very different from those of the constituent metals. Trace impurities can greatly change the temperature coefficient. Sometimes trace amounts of "impurities" are intentionally added to eliminate the effect of removing uneconomical and unwanted impurities. Other alloys can be customized for specific temperature characteristics. For example, 84% copper, 12% manganese, and 4% nickel alloys have properties that respond to almost zero temperature. This alloy is used to make precision resistors.

Type of RTD temperature sensor

RTD temperature sensor type

Platinum is by far the most common RTD temperature sensor material, mainly because of its long-term stability in air. There are two standard Platinum sensor types, each with a different "impurity" doping level. To a large extent, platinum RTD temperature sensor standards have converged, and most national standards institutions have adopted international IEC751-1983, revised in 1986 and revised in 1995. The United States continues to maintain its standards.

All platinum standards use a modified polynomial called Callendar – Van Dusen equation:

R(t) = R 0 ( 1 + at + bt 2 + c.(t – 100). t 3 )

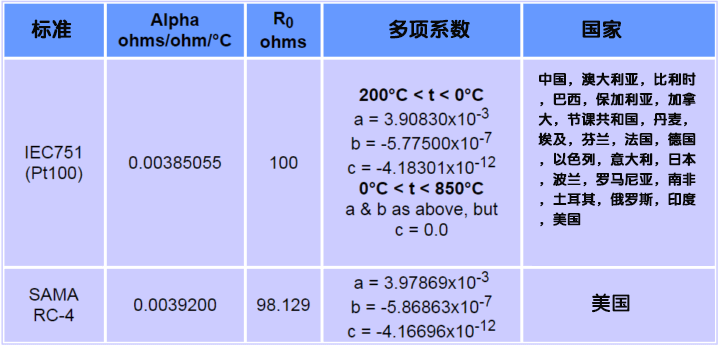

Platinum RTDs have two temperature coefficients or alpha values - the choice depends on the national preference of your country, as shown in the following table: