How to install heat suite on the elbow?

How to install heat suite on the elbow?

People prefer to install hot electric puppets sleeve the most important reason for it is that it can save Awakening frequency calculation (WFC).

Therefore, it is essential to effectively install the thermocouple sleeve to achieve its expected purpose.

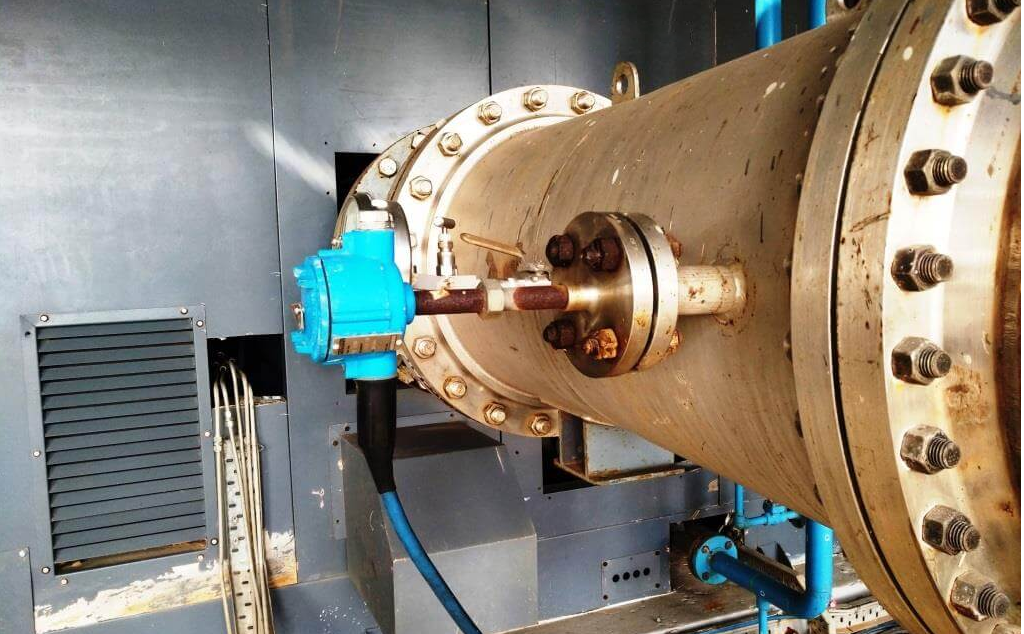

The installation of heat suite

There are 4 main parameters need to be checked

1. The flow direction in the pipeline (the tip must face the direction of flow)

2. Accept other disciplines, especially the process department

3. Clear space for external temperature components

4. It is easy to access when the test well

Why do you want to check the flow?

When the object is vertically placed, the vortex will form.

Now, when we install the thermocouple sleeve in the elbow, our goal is to make the thermocouple sleeve with the "vertical" flow as much as possible

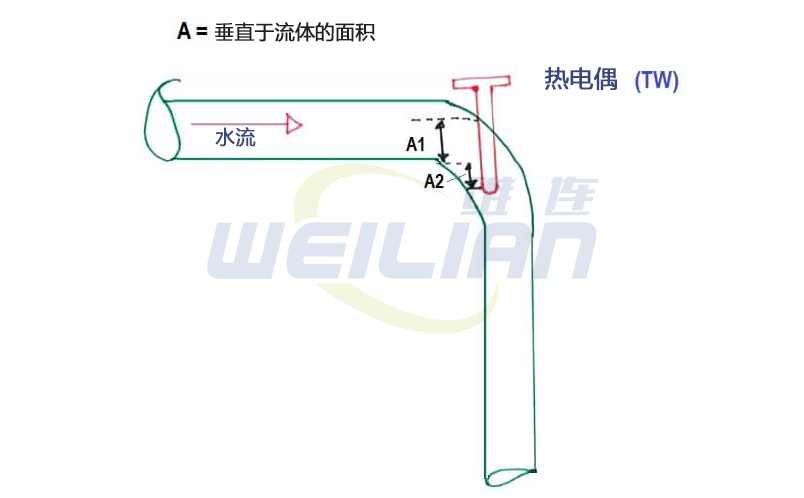

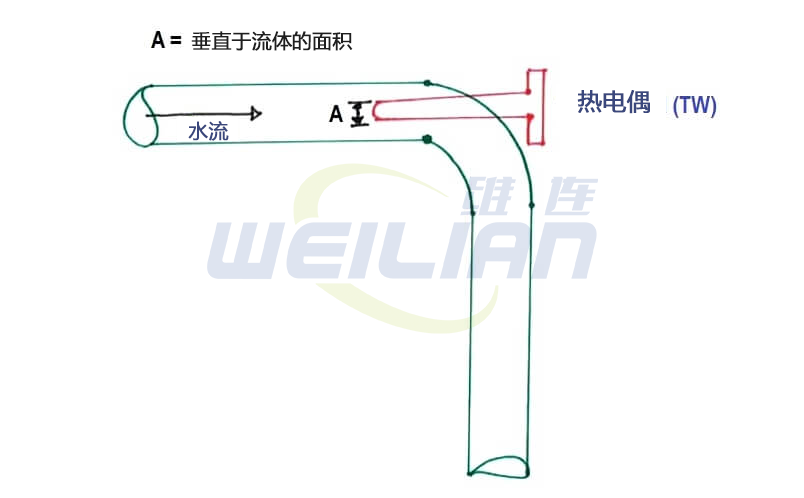

Case one -tip facing downstream of bending pipes

It can be clearly observed that more vertical areas exposed to flowing are more

Compare it to the tip of the upstream of the bending pipe

Picture

We can see that when the tip faces upstream, the "vertical" flow area is very small

Therefore, Von Karman's vortex is very small, so the pressure on thermocouple sleeve is less pressure

As shown in the figure, the hot sleeve tube installed in the elbow and the tip of the tip to the upstream is usually more desirable than the installation of the downstream of the tip.

Note: The world's main petrochemical company mentioned in its design base that WFC should comply with Asme PTC 19.3

The recognition of other disciplines?

Below, the picture assumes that our heat suite is in this position

Now we may think that we can install it in the bending pipe, but wait for another line to join our line in the middle.

Therefore, the process may need to measure the temperature of the liquid before mixing, so even if we meet other considerations, we still cannot install ELBOW.

The gap between the hot sleeve?

This is easy to understand if you want to unload or install the thermocouple sleeve or install it outside.

There must be some gap space to physical remove the temperature component.

It should be about 610 mm (24 inches)

or

The total length of the thermocouple sleeve is + 76 mm (3 inches) ...

It is easy to access when the test well

It is recommended that the test well must be very easy to approach, so if the bending pipe is at a high height, it must be discussed and a friendly solution is required.

In some cases, I noticed that customers do not accept bending installation because they want to test wells.

Thank you for reading! Intersection

I hope it is valuable to you.