Calculation frequency calculation of hot sleeve wake -up frequency

Calculation frequency calculation of hot sleeve wake -up frequency

What is the frequency calculation of the hot tube awakening frequency?

Awakening frequency calculation is used to determine or prove the size and applicability required for the thermal sleeve according to the process conditions. The fluid will form a tail flow, known as "Fengka Gate Trail".

The tail current has a specific frequency, which is a function of the diameter of the heat suite and the fluid speed. If the tail flow frequency is consistent with the natural frequency of the thermal sleeve, the well will vibrate and cause damage.

Thermal puppet

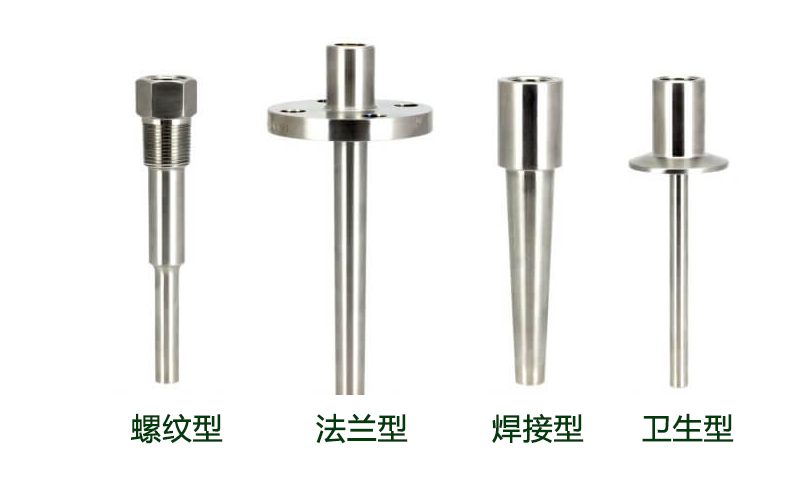

The thermocouple sleeve is mainly used to use the application that needs to measure temperature in high voltage (above 75 PSIG) or harsh environments.

They are also used for isolation, so the sensor can be replaced without turning off the process. The hot tube is processed by solid stick materials.

Safe work pressure depends on the speed of the well, operating temperature and flow medium.

Hot cover tube vibration

When the fluid flows through the heating tube, the changes in the fluid momentum will generate turbulent tail flow after the well.

The vortex is formed in this tail and flows out of the sides of the well. The vortex foster frequency (or the tail flow frequency) is linearly related to the flow rate, which is inversely proportional to the tip of the heating tube.

These falling vortex flows on the thermal puppet tube, a periodic force composed of two components- (i) lift, perpendicular to the flow direction, oscillation of the tail flow frequency, and the small resistance of (ii), parallel in parallel in parallel on Flow to wake up the frequency at twice the frequency.

The force caused by these vortex can cause the vibration of the heat suite, usually small, and the amplitude of the vibration can usually be ignored.

However, as the tail current (FW) is close to the inherent frequency (Fn) (within 20%) of the thermal sleeve, it will offset and lock it to the inherent frequency.

When FW = Fn, the heat suite enters the resonance state, and the vibration force increases rapidly. The vibration causes the mechanical failure of the well.

Murdock calculation (and supporting ASME PTC 19.3) only regards the oscillating lift as the reason for the vibration of the tube. The ratio of tail flow to the inherent frequency is limited to a maximum of 0.8 to eliminate the possibility of resonance.

Although the oscillation resistance is small, it can force the heat suite to resonate at a lower speed because it occurs at twice the frequency of tail flow.

For high -density fluids (liquid and high -voltage steam), Murdock analysis is not enough. When containing an oscillating resistance component, the speed rated value can be reduced by up to 50%.

The calculations included here are modified to include online resonance, correction rate, and actual natural frequency of use wells caused by oscillation resistance, not estimates.

These calculations can only be used as a guide to select the correct thermal suite. Other variables, such as corrosion, should be evaluated and influenced decision -making.

Thermal sleeve speed calculation

When the fluid flows through the heating tube, a low -pressure vortex flows in the lower reaches of the well.

These vortex flow out of the other side of the thermocouple, which generates two cyclical force on the heat suite:

(i) fluid flow with oscillation, horizontal to frequency FS

(ii) Optoma resistance, consistent with fluid flow with frequency 2FS

The vortex may occur at the frequency of 50Hz to 1500Hz. The vortex drop frequency (Strouhal frequency) increases linearly linearly with the flow of the stream, but increases with the square speed.

When the Strouhal frequency is close to the natural frequency of the thermal sleeve, it locks to the natural frequency, which will cause resonance and greatly enlarged.

To prevent locking, the inherent frequency of heat suite must be higher than the coaxial or horizontal resonance conditions.

Only under resonance can only be operated through the series of resonance under the circumstances that the cycle stress under the resonance conditions is small.

The fluid speed when resonance occurs is called critical speed. There are two speed peculiar values for each inherent frequency of the heat suite: one describes horizontal, and the other describes online response.

Because the axial force fluctuates with twice the frequency of the horizontal force, the corresponding critical speed is about half of the horizontal resonance.

If the inherent frequency of the thermocouple sleeve overlaps with FS or 2FS, a large resonance amplitude may occur. The main cause of thermal tube failure is the fatigue caused by resonance.

The high enough damping level can allow heat suits to work at the frequency of connecting or even horizontal resonance.

In addition to the frequency limit, the stress and exerting force in the heat cover tube are also critical to evaluate the application of the heat suite for the application of specific processes. The 4 fixed volume standards to be evaluated are:

1: Frequency limit:

The resonance frequency of heat suite must be high enough so that fluid flows will not stimulate destructive oscillations. Stabilization (SS) fluid speed should meet one of the following conditions:

FS (SS) <0.4 • Fn or 0.6 • FN <fs (SS) <0.8 • Fn

2: Static stress limit:

The steady -state stress is the result of fluid static pressure and the non -oscillating resistance on the heat suite, and is calculated at the maximum stress location.

If the hot sleeve is partially shielded or has a reduced tip, these factors must be considered when calculating.

The maximum steady -state stress on the design speed shall not exceed the allowable stress determined by the Von Mises standard.

3: Dynamic stress limit:

Dynamic stress is the result of the periodic resistance that leads to a periodic oscillation and the periodic lift that causes horizontal oscillation.

If the thermal tube intends to run without the critical value of the tandem speed, the circulating stress of the series resonance at the process of reaching the design speed can be considered in the process of reaching the design speed.

The maximum dynamic stress must not exceed the limits of fatigue stress. Calculate the amplifier coefficient and apply it to the cycle stress equation, and then calculate the cycle resistance and lift at the design speed.

The maximum combined lift and resistance stress must not exceed the fatigue stress limit.

4: Static water pressure limit:

At the working temperature, the external pressure must not exceed the minimum pressure rated value of the tip of the heating tube, handle or flange (or thread).

Thermal set standard

ASME PTC19.3-1974 has been the standard for designing most thermocouple sleeves for many years.

This standard is only suitable for cone profiles, and does not consider stress caused by oscillating resistance.

Asme PTC19.3TW-20110 is a new standard released in July 2010, which is used to replace the 1974 standard.

It uses a more advanced method to evaluate the applicability of the thermocouple sleeve on a specific application, and it is suitable for cone, straight, and narrowing the tip.

Calculation frequency calculation of hot sleeve wake -up frequency

Calculation of thermal wake -up frequency calculation is usually carried out before the hot suit manufacturing.

They ensure that the design of the heating tube is strong enough to cope with various stress and response generated by the media.

Awakening frequency calculation data can be used for the following basic parameters:

● Stress

● Temperature

● Speed

● viscosity

● density

Any heat suite failure will occur at the highest stress point, that is, between flange/shaft joints. Except for the speed ring (which can cause their own problems and not recommended in the current ASME PTC 19.3 TW-2010 standard), this has traditionally shortened or increased the thickness of the heating sleeve.

Both technologies will significantly increase the response time and are not conducive to temperature measurement performance.