What is platinum resistor temperature sensor -introduction

The most popular RTD temperature sensor measurement device is the PT100 temperature sensor. In the process industry, the PT100 temperature sensor is widely used to measure extreme temperature, with coverage from -200 to +800 ° C.

In addition, the sensor type represents two important factors of the sensor. The first factor PT is a chemical symbol of platinum, which indicates that the sensor is made of platinum, because until today, platinum is still used as the main element of all high -precision resistance thermometers. The second factor 100 represents a 100 ohm resistor, which is related to the resistance of the device at 0 ° C.

The T10-PT100 temperature sensor has excellent accuracy, wide temperature range, and the best position of various applications.

1) excellent accuracy at extreme temperature

PT100 is one of the most accurate temperature sensors. There are 3 different methods for measuring resistance, which are 2 lines, 3 or 4 connections. The 2 -line connection is generally suitable for measures with extremely low accuracy, because any wire resistor or connection resistance will bring errors to the results.

Any normal process measurement should be completed at least 3 line connections. The Weilian T01-PT100 uses a 3-line connection to measure the compensation cable resistance to ensure the accuracy of the collection of temperature data.

2) Platinum probe suitable for wide temperature range

Platinum has a positive resistance temperature coefficient; the resistance increases with the temperature increase. Although platinum is a precious metal, it is very expensive, but compared with any other materials, it has higher linearity and stability.

The temperature range of the default measurement of Vilian T01 -PT100 is -50 to +200 ° C, and it can expand the range from -200 to higher temperature +800 ° C through different sub -models.

3) Adapt to the design of multiple applications

The T01-PT100 is equipped with a variety of high-precision platinum resistance thermometer probes.

The direct tube T01-PT100 probe can be used for general industrial departments, such as measurement operations under extremely humid atmospheric conditions.

In addition to direct tube types, you can also obtain other types of probes through customized services, including armor, rings, magnets, threads, and SMT. They can also help the T01-PT100 sensor work steadily in the application of vibration, and minimize the impact of turbines, pumps, compressors and other industrial equipment.

In addition, the independent lithium battery inside the sensor makes it unwilling to be affected by electrical noise, so it is very suitable for temperature measurement in a harsh industrial environment.

4) Response time

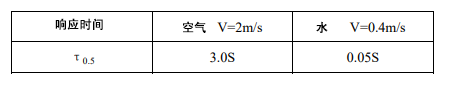

When the temperature changes with the stage, the output of the thermocouple will change to 50%of the change at this stage. The required time is called the hot response time, which is represented by τ 0.5.

The factors that affect the τ 0.5 are related to the material, diameter, thickness, and the structure, installation method, insertion depth of the protection tube, the flow of the measuring medium, and the types of the measuring medium.

The typical data value of the component response time is as follows:

5) RTD VS thermocouple/thermal resistance resistance

Finally, another question that customers often ask are the difference between the RTD temperature sensor and the thermocouple or thermal resistance. Then, each temperature sensor has its own marketing positioning and the most suitable situation. The resistance temperature detector has the following advantages:

● Wide temperature

● High accuracy than thermocouple

● Long -term stability

● High -precision: A -level A with IEC 60751

Benefit

● Weilian T01-PT100 temperature sensor as a professional sensor manufacturer, with excellent hardware performance and high data accuracy.

● Use NFC technology to easily configure

● Easy deployment through wall -mounted installation/pole installation/DIN RAIL

I ● P67 wind and rainproof waterproof shell

● For air, water and any benign and corrosive environment (depending on the type of probe)

● Maximum. 10 years of battery life (depending on use)

● Various probes of Victoria provided various configurations

● T01-PT100 resistance thermometer does not require additional calibration

● Platinum RTD temperature sensor is the most linear, stable and most accurate among all RTD temperature sensors, without measurement errors

Typical Application

● Ultra-cold refrigerator (-80 ° C)

● Refining, petrochemical

● Electric energy industry

● High vibration application: turbine, pump, compressor

● Plant processing

Selecting 7 steps for the appropriate temperature sensor

Let's review the first 7 factors that need to be considered when selecting the appropriate platinum resistor temperature meter or RTD temperature sensor or PT100 RTD temperature sensor.

1) Component type

Do you know the type of the RTD temperature sensor component? In addition to the platinum PT100 temperature sensor or PT1000, other materials such as nickel, nickel iron alloy and copper have also been used for RTD temperature sensors. No matter what medium you connect to the RTD temperature sensor, you must first confirm the factor.

2) Measurement medium

Do you use the sensor for the surface of gas, liquid or material? Where will you deploy a probe? Do you have to put the probe in a certain thing or fix it with something?

3) Temperature range

This is the basic factor because it determines the component type and sub -model of the EM500 -PT100 model from -200 to 800 ° C.

4) Deployment location

What type of probe can help you fix the RTD best, depending on the location, such as wall -mounted, compact, magnetic, SMT, etc.

5) Working environment

IP67 protection level and anti -corrosion protection are sufficient to meet your needs? Do you need it to pass ATEX certification, safety and vibration resistance to food production?

6) Physical considerations

What are the requirements for length, diameter and size? Do I need to bend or long?

7) Wiring