Thermocouple temperature measurement error

Thermocouple temperature measurement error

What is the main source of error in thermocouple (TC) measurement?

Basically, TC's behavior is very predictable -it is either effective or invalid. Having said that, some things will appear over and over again, making it work.

In short, there are four main reasons for you will have errors in TC measurement:

1) Select the wrong TC type -

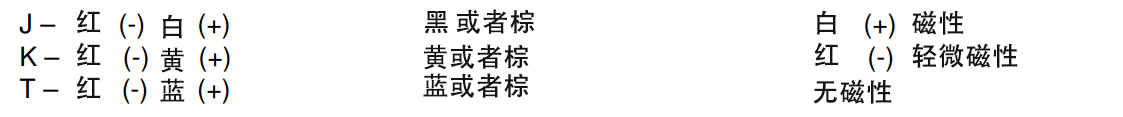

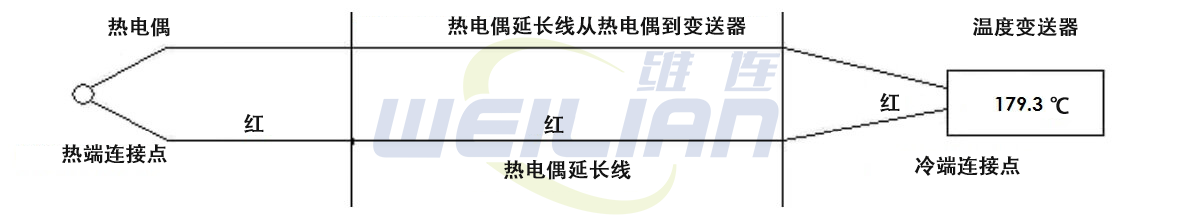

The TC type selection in the transmitter must always match the TC that is being used. This error often occurs. Different TCs have different curves, different range and different MV outputs, so everything must be matched. The most common types are J, K and T. 1 Since TC is color -encoded, it is easy to check:

2) TC knot error -

Because the alloy is not perfect, TC has inherent mistakes. They are slightly different due to batch production. Because you are processing a micro voltage, you don't need too much to close a little bit. The standard TC is usually about 1%of the temperature measured at the node. The accuracy of the special limit is doubled, and the accuracy of the three times limit increases by 4 times. 1 Therefore, your accuracy is limited to the accuracy of the TC knot. In addition to specifying special restrictions, you have no power about this error.

3) The connection to the TC extension line is another major source of error.

Please note that the red line is as shown above. If the TC extension line is reversed, TC can still work. It is just that the temperature difference at both ends of the extension of the line will be wrong. do not laugh. We have seen this many times.

The TC extension line has a matching TC type. It must be their respective TC cables, not copper wires

Do not run the TC extension line in an overheated or cold environment. Its rated temperature is only 0 ° C to 200 ° C (T type is -60 ° to + 100 ° C)

Another error source is the plenty of thermal connection, the unsolved barrier and the wiring nut. TC materials should be connected to TC materials instead of connected to the barrier. If you want to use the barrier bar, put the TC wire under the same screw, or order the TC material wiring film. If you use a thread nut, twist the TC line together. When you twist it, the J type often breaks (sooner or later). If you don't care about 2 ° -3 °, you don't need to worry about TC wiring films.

If you are looking for extremely high accuracy, do not use the TC extension line. Use the original TC line to run the entire length. The TC extension line is only designed for the accuracy of the standard TC line. Every time you convert to the new TC line, the TC error will be added again. Use a wire carefully in laboratory applications.

Finally, you can use TC transmitters. The price of these guys has fallen to $ 150. The transliteration, compensation and linear TC at the source are eliminated, eliminating the TC extension line. Most TC transmitters provide 4-20 mA within the scope of interest.

4) Another important error source is cold compensation

TC measures at the temperature difference between the two ends. Therefore, the more accurately you can measure the cold end, the more accurate the TC can be measured. The cold end is usually specified as 1 ° or 2 °.

Although the cold -end specifications may be okay, how to connect to the cold end is another problem. You should bring the TC into the instrument with a small circle near the instrument. This idea is to make the TC approach the temperature of the instrument at the cold end. Due to the temperature difference, the fan or thermal source near the TC connection of the instrument will produce a large error. Sometimes a small piece of foam on the TC terminal can produce a large difference.

In order to find your TC's accuracy, you must add up all errors. Some you can improve, some are just the nature of the beast. Remember, TC will measure the temperature during its entire operation,

By the way, perform some fast tests to ensure the correct connection of TC -put the handle around it. The temperature should rise. If it drops, it is backward. If you will be short -circuited, it will read room temperature.