What is thermocouple and thermal resistance temperature sensor cable?

The nail heating puppet is made of two wires from different metals. These two wires are connected together to form a temperature measurement knot. Each wire is made of specific metal or metal alloys. For example, the positive (+) conductor of the K-type thermocouple is made of chromium/nickel alloys called nickel chromium alloy, and the negative (-) conductor is made of aluminum/nickel alloy called nickel chromium alloy. The line used to make thermocouple knot is called the thermocouple line.

Thermal electricity

As shown in the figure, when the temperature of the measuring (thermal) knot and the reference (cold) knot is not at the same time, due to the so -called Sebeck effect or the thermoelectric effect, the thermocouple circuit will generate voltage. This effect can be considered a small battery, and its output voltage is proportional to the temperature of the measurement knot.

The generated voltage is within the millival (MV) range and varies from type of thermocouple. The voltage is measured by electronic devices and converted it to temperature reading.

Measurement Side

There are three main types of measuring joints. An open -end without protective cover. The end of the A -connecting ground has a protective metal cover such as stainless steel, which surrounds the conductor and insulation. This connection type is more durable and more resistant to corrosion than exposed connections. An undisturbed knot is similar to the ground end except the thermocouple wireless wire is connected to the metal sheath. This knot can better prevent electromagnetic interference.

Reference Access

As mentioned earlier, a reference (cold) knot is needed in the thermocouple circuit. Because the voltage read read in the instrument is actually proportional to the temperature difference between the measurement node and the reference node, it is necessary to know that the temperature of the reference node can be determined to determine the temperature at the measurement node. In practice, references are often introverted in temperature records or process control instruments.

Therefore, users usually "invisible" reference. The thermocouple is connected to the extension line, and the extension line is connected to the process control instrument.

Thermocouple type

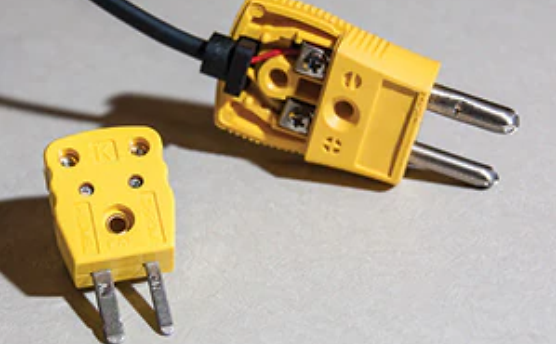

The industry specifically identifies different types of thermocouples and thermoelectric puppet lines, and uses a letter to represent each type. Some common types are K, J, T and E. Different thermocouple types have different temperature range, and they can be successfully used. The ISA/ANSI standard MC96.1 specifies the chemical composition of each thermocouple alloy, the allowable temperature error limit, and the color code of each thermocouple type. From the perspective of application, the important point that needs to be remembered is that the type of thermoelectric puppet line must be matched with the thermocouple type.

Extension line

The types of thermocouple extension lines such as KX, JX, TX, and EX are used to connect the measurement to the temperature records or process control instruments. This may be a distance of hundreds or even thousands of feet. The extension line is usually exposed under temperature and other environmental conditions, and these conditions do not measure the extreme situation encountered in the measurement. Therefore, the "extension" -class wires will not be calibrated above 400 ° F (204 ° C), and the materials with lower rated temperatures are usually used for insulation and sheaths. Because the low -voltage instrument signal is transmitted, the thermocouple extension line is usually blocked.

Resistance temperature detector (RTD)

In addition to thermocouple, there are other temperature measurement technology, such as RTD temperature sensor (resistor temperature detector). Use thermocouples in applications with temperature higher than 1,200 ° F (650 ° C). At lower temperatures, the RTD temperature sensor is used for its simpler operation and higher sensitivity and stability. The thermocouple has a better response time. The RTD temperature sensor is a special resistor, and its resistance value changes with the temperature in a known way. RTD temperature sensor uses ordinary copper instrument cable to connect to temperature records or process control instruments. Connecting RTD does not require the thermocouple line.

The typical RTD temperature sensing cable is the standard instrument cable of two, three or four conductors, or it may be a pair/ three -line group/ four -line group , Specifically depending on the type of RTD temperature sensor and the number of monitoring equipment. Soloin or overall shielding is usually used for noise resistance.

| Thermocouple level | Extension level | Conductor Color |

Alloy | ||||

| ANSI code | Terminal Color |

Terminal color | Positive | Negative | Positive | Negative | Temperature range |

| J | Brown | Black | White | Red | Iron | Copper Nickel | -210 ° to 1,200 ° C -346 ° to 2,193 ° f |

| K | Brown | Yellow | Yellow | Red | Nickel Chromium | Nickel Aluminum | –270 ° to 1,372 ° C - 454 ° to 2,501 ° f |

| T | Brown | Blue | Blue | Red | Copper | Copper Nickel | –270 ° to 400 ° C - 454 ° to 752 ° f |

| E | Brown | Purple | Purple | Red | Nickel Chromium | Copper Nickel | –270 ° to 1,000 ° C - 454 ° to 1,832 ° f |

Table 1: Types of thermocouple line and thermocouple extension line