Resistance Temperature Sensor Temperature measurement error

Resistance Temperature Sensor Temperature measurement error

resistor temperature sensor The errors in temperature measurement are naturally divided into four categories. All errors are relatively easy to identify the cause and separate various functional components in the structure

immersion error:

For the temperature measurement of the resistor temperature sensor, the sensor element is very large.

The freezing point may be difficult, especially the stainless steel sheath PRT; the combination of thermal shots and self -heating makes it difficult for the freezing point to achieve better than ± 0.01 ° C.

The important thing is that the ice cubes should be very fine and packed well. For measurements that require more accuracy than ± 0.01 ° C, the water should be used priority.

Has lag and stability error:

Error caused by the response time of the instrument. The time constant of the PRT changes greatly: the type of film is 0.2 seconds; for the larger complete and partial support type, it takes 2 to 6 seconds; the SPRT 5 seconds; the stainless steel sheath component is 5 to 20 seconds

Radiation error:

The long -term resistance thermometer protective cover provides a transparent "optical tube". Radiation can pass the heat along the "optical tube" to transmit heat from the sensor element to the sensor element.

Due to radiation, PRT not only contacts the medium heat around the platinum element, but also radiates with any substance under it in it.

Self -heating:

As the current passs through the sensor element to measure its resistance, the component will emit calories, which will cause the temperature of the component to rise.

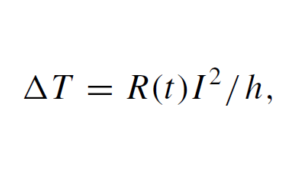

This self -heating error can be very simple to moderate to dissipate power to remove constant H. Temperature measurement error is

Among them, R (T) is the resistance of the sensor element, and i is the sensing current. The dissipated constant H is usually represented by millwatter/degree Celsius.