What are thermocouple temperature sensor cables and wire materials?

What are thermocouple temperature sensor cables and wire materials?Temperature is one of the most important measurement units of industrial monitoring. It is extremely necessary to temperature as accurate as possible. Without correct management, it may lead to poor quality items. It smells very fragrant perfumes, and now smells very ordinary. Food may have different tastes, or improper management of temperature in the medical field may cause items that cannot be used by donations, such as blood.

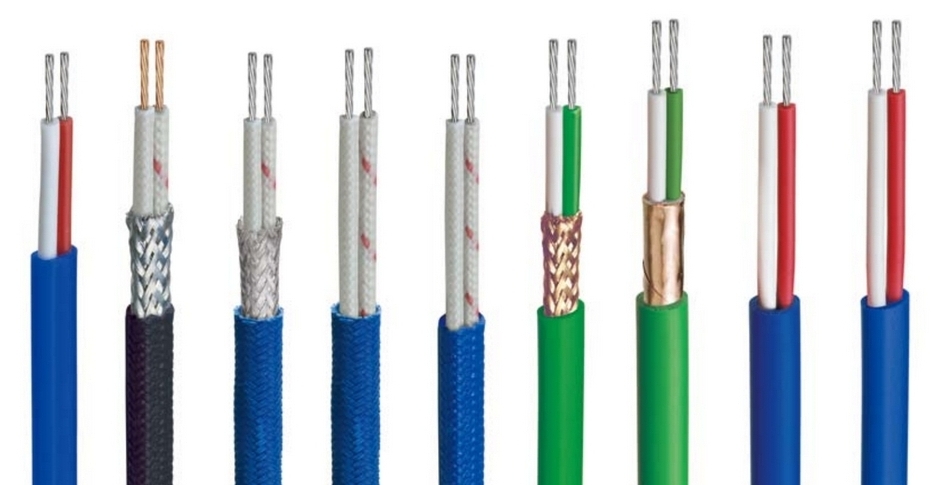

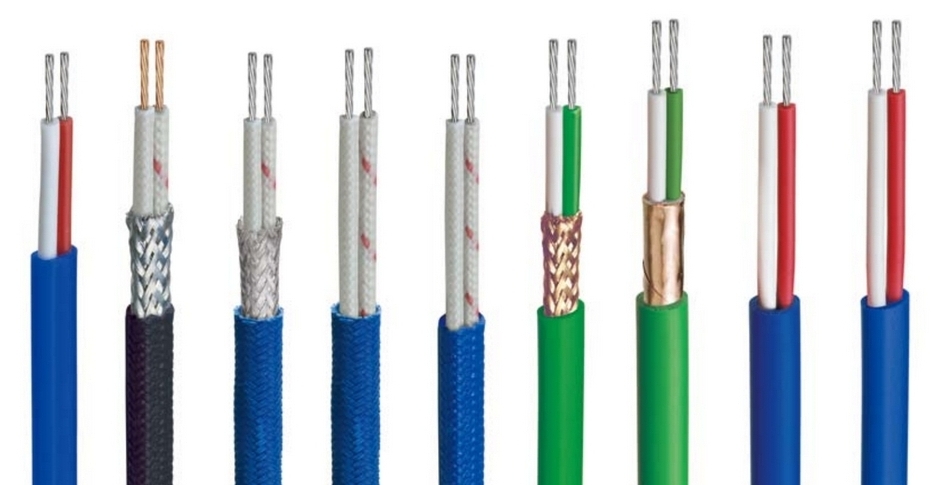

The thermocouple temperature sensor is a commonly used temperature sensor. The wire and cable of the thermocouple temperature sensor are an important part of the structure because they complete the circuit between the thermocouple and the RTD controller. In essence, what kind of carrier signal is converted from thermocouple to thermal resistance to a accurate temperature reading. The exogenous insulation of the thermocouple wire and some single conductors is color -encoded to facilitate identification.

Various high -performance materials are used to provide various temperature sensor wires and cables. They are all produced with the highest quality. Here are different materials used in thermocouple temperature sensor wires and cables, as well as applications they can use for.

Synthetic Fiber -This fibers are made of flexible ceramic fiber yarn and can survive at high temperatures. The insulation layer is covered on the coat and a single conductor.

There are many applications suitable for using these cables, including:

Hiking Treatment

Iron and Steel Plant and Aluminum Factory

Made in glass, ceramics and brick tile

Replace the beaded heat electric puppet

Soaking Pit

Glass Fiber -The entire protective cover and single -rooted conductor are protected by glass fiber fabrics. In terms of insulation, dip the cable with high temperature resin.

The appropriate use of glass fiber wires and cables includes but not limited to:

Iron and Steel Plant and Aluminum Factory

Hiking Treatment

Casting Factory

Glass, ceramics and brick factories

Plastic processing equipment

Each conductor and coat have separate colors. This is a relatively cheap insulator. Because these cables are made of PVC, which makes them easy to be stripped and separated, which makes it more flexible and easier to assemble. The wires are also produced in a multi -pairing structure, including copper drainage lines. This means that each pair of conductors are wrapped alone with aluminum bands.

Applications for PVC wires and cables include:

Laboratory

Industrial Equipment Test

Car

Test facilities

Each monolithic and outer clocks use layered . These wires are well -known special moisture, chemistry and wear resistance.

Applications suitable for using wires include:

Industrial Equipment Test

Power Plant

Petroleum Factory

On -site thermal treatment

Tape-TFE tape is suitable for each conductor. After that, they are hot-melt and then the tape is applied to the conductor to make the entire coat. The hot melt band makes the cable structure a solid component. These metal wires have excellent moisture -proof, chemical corrosion and abrasion resistance.

tape wires and cables suitable for many applications, including:

Plane composite material bonding

Power Plant

kiln

Petroleum Plants

Glass, ceramics and brick factories

What are thermocouple temperature sensor cables and wire materials?

What are thermocouple temperature sensor cables and wire materials?