The RTD temperature sensor has become the most commonly used industrial temperature measurement instrument due to its multifunctional, accuracy, repetitiveness, easy installation and relatively wide measurement range. Although it has all advantages, RTD is more expensive than industrial thermometers or thermocouple puppets, and can be used to measure temperatures up to about 538 ° C.

How does RTD temperature sensor work?

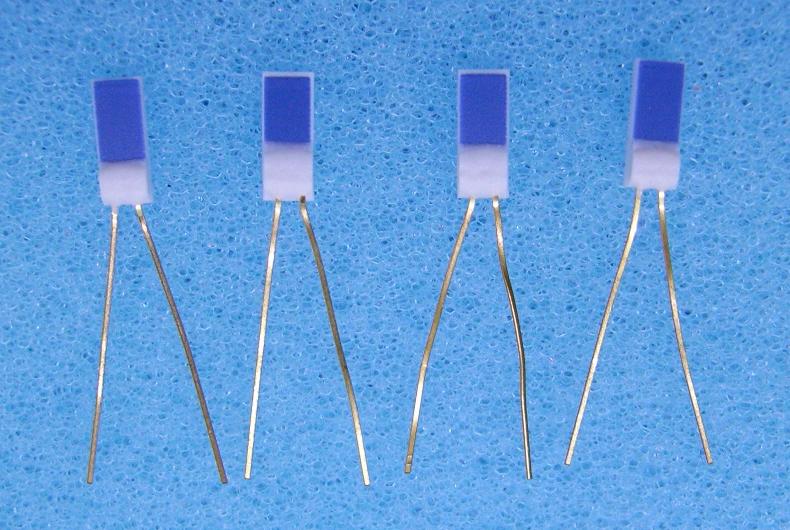

The functional unit in RTD is a sensor element that uses the changes in the resistance in the metal wire (usually platinum, copper, or nickel) to determine the temperature change. The resistance of the wire at a specific temperature is known, so the known resistance can be used as a constant to compare with the resistance at that time to calculate the temperature change of the target object. The RTD sensor can be produced as:

● The winding RTD component is made of metal wire, wrapped around the glass or ceramic line shaft, and then covered and sealed with glass.

● Some supporting winding RTD components are formed by the coils at the bottom of the opening of the hollow ceramic insulator opening.

● Film RTD component, deposit a thin layer of platinum or other metal glass on the ceramic substrate. Although the film sensor is more accurate and has a longer service life, they cost higher than other types of resistance thermometer sensors.

Why is platinum the most popular metal of the RTD temperature sensor?

Platinum (PT) has a variety of characteristics, making it very suitable for RTD sensing elements or RTD sensors. First, it has extremely high chemical inertia. This strong precious metal has the relationship between almost linear temperature and resistance, and has sufficient large resistance temperature coefficients. It can generate measured resistance with the temperature of the temperature. Platinum also allows the sensor to generate a stable temperature reading, because the platinum resistance will not decrease over time. The only main disadvantage of platinum is high cost.

Why is platinum the most popular metal of the RTD temperature sensor?

Why is platinum the most popular metal of the RTD temperature sensor?