Advantages of sheathed thermocouples

Advantages of sheathed thermocouples

The thermocouple temperature sensor is rugged and can respond to temperature changes quickly. When sheathed, these temperature measuring instruments are highly resistant to vibration, mechanical stress and aggressive/corrosive media. Because of their small size and highly flexible, sheathed thermocouples are ideal for use in narrow spaces.

What are sheathed thermocouples?

Robust and responsive thermocouples are widely used in a variety of applications and are an inexpensive temperature measurement solution.

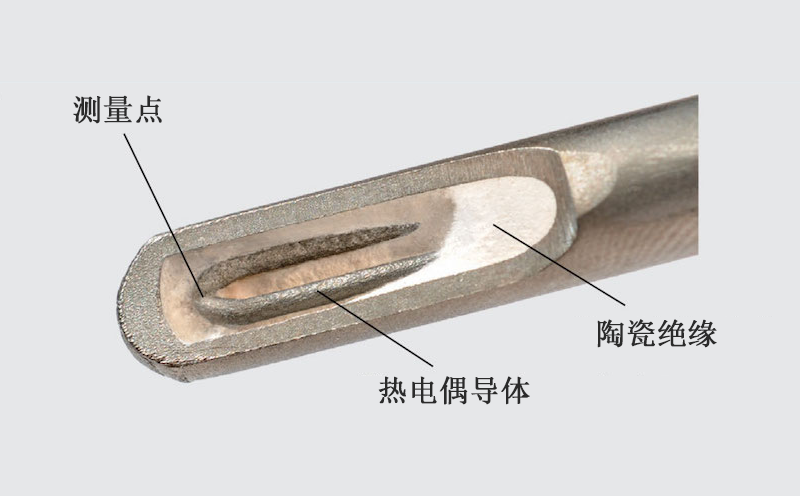

The thermocouple consists of two different metal wires connected at the measuring point (hot junction). The other end is the reference point (cold end), where the temperature is a constant and a known value. As the temperature of the measuring point rises, different metals will produce different voltages (Seebeck effect). The voltage difference at the cold end corresponds to the temperature at the hot end.

The sheathed thermocouple is a kind of thermocouple, in which the wires are inserted and insulated by high-density ceramic compound (usually magnesium oxide), and then wrapped in a metal sheath. The common sheath material is stainless steel or alloy 600, but any metal that can be cold worked can be used.

Advantages of sheathed thermocouples

●Vibration and shock resistance。Metal sheaths and MI cables protect conductors from shock and vibration, prevent breakage, and make sheathed thermocouples highly resistant to mechanical stresses.

●Corrosion resistance and corrosive medium。316 stainless steel has good resistance to corrosive media and steam and smoke in chemical media. The corrosion resistance of Alloy 600 makes it particularly suitable for thermocouples that must handle high temperatures. It can also withstand cracking and pitting in chlorine containing media, as well as corrosion caused by hydrogen chloride or ammonia in aqueous solution.

●Small and flexible。The protective metal sheath allows the use of thinner conductors and a more compact design than sheathless thermocouples. The diameter of sheathed thermocouple can be as small as 0.25 mm (0.010 inch) without affecting the integrity of the instrument. The metal sheath is also flexible, allowing bending without damaging the sensing element. Therefore, sheathed thermocouples are particularly suitable for temperature measurement in narrow spaces and corners.

●Conductivity and High Temperature Limits。The metal sheath can withstand very high air temperatures: 316 stainless steel up to 850 ° C (1562 ° F), alloy 600 up to 1200 ° C (2192 ° F) – depending on the thermocouple type. The jacket also provides better heat conduction than an unsheathed thermocouple, reducing thermal lag time and resulting in faster response.

Weilian produces a complete series of K-type, J-type, N-type, E-type and T-type sheathed thermocouples. We also manufacture R-type, S-type and B-type thermocouples for various temperatures and applications. For more information, please contact a maintenance expert.