What you need to know about industrial thermal resistance temperature sensor

What you need to know about industrial thermal resistance temperature sensor

Wire wound resistors and film resistors are widely used in industrial temperature sensors. It is very important to select temperature equipment with appropriate materials, design and configuration to meet the requirements and comply with DIN EN 60751 resistance temperature sensor standard.

A resistance temperature sensor uses a sensor whose resistance varies with temperature. Materials used for resistance temperature sensor sensors - also known as RTDs or resistance temperature detectors - have a positive temperature coefficient, which means that the resistance of the sensor increases as the temperature increases. Correct materials, design and configuration will have a positive impact on the performance and service life of industrial resistance temperature sensors. It is also important to compare the accuracy and vibration resistance specifications with the DIN EN 60751 standard.

Material: Pt100 and Pt1000

Although copper or nickel can be used, the wires in most industrial resistance temperature sensors today are made of platinum, which is a metal with very stable resistance in a wide temperature range. The nominal resistance of RTD with Pt100 sensor at 0 ° C is 100 Ω. The nominal resistance of the sensor with Pt1000 sensor at 0 ° C is 1000 Ω. The Pt100 sensor is cost-effective and is the most commonly used sensor in the world. Pt1000 sensors are more expensive, but they have greater resistance to temperature changes, so their resolution is higher. Other advantages of Pt1000 sensors: They reduce the impact of lead resistance and have longer battery life.

Design: winding and film

In a wound wire (W) resistor, a thin platinum wire is either melted in the glass body or spirally combined in the cylindrical cavity of the ceramic protector.

W glass resistor has strong vibration resistance. However, high temperatures can change some of the properties of glass, thereby reducing accuracy. Manufacturing W glass resistors is relatively difficult and expensive.

W ceramic resistors provide a wider operating temperature range (– 196 to+600 ° C) than W glass resistors, but the helix is prone to fracture when subjected to high vibration.

In a thin film (TF) resistor, a fine platinum film is deposited on a ceramic plate. Then seal the film, plate and wire connector with a glass layer. TF has very small resistance, good vibration resistance and very affordable price. However, the different materials in each resistor (platinum film, ceramic plate and glass layer) limit the operating temperature range of the resistor to – 50 and+500 ° C. Special TF elements have a wider temperature range but are more expensive.

2-wire, 3-wire and 4-wire configurations

The basic 2-wire connection is the simplest configuration. It is also the least accurate because the internal lead resistance of the wire is added to the measurement. This configuration is not recommended for Pt100 measurement circuits when Class AA or Class A tolerances are required. However, when combined with the PT1000 sensor, the 2-wire configuration will become more accurate, because the higher resistance of the sensor will reduce the relative impact of the connecting cable.

In a 3-wire configuration, the third wire is used to evaluate and compensate the resistance of the connecting cable. The 4-wire configuration not only eliminates the effect of connecting cable resistance, but also compensates for any asymmetry in the cable. The 4-wire configuration allows the longest cable length and the smallest error rate.

standard:DIN EN 60751

The latest update of DIN EN 60751 (2009) revised the recommendations for platinum resistance temperature sensors. This standard provides guidelines for several accuracy classes (AA, A, B, C) for wire wound and film resistors. These ratings are based on resistance tolerances and RTD measurement temperatures at different operating temperatures, AA being the most accurate. The standard also provides recommendations on vibration resistance, although they are ambiguous. (See this article for more details.)

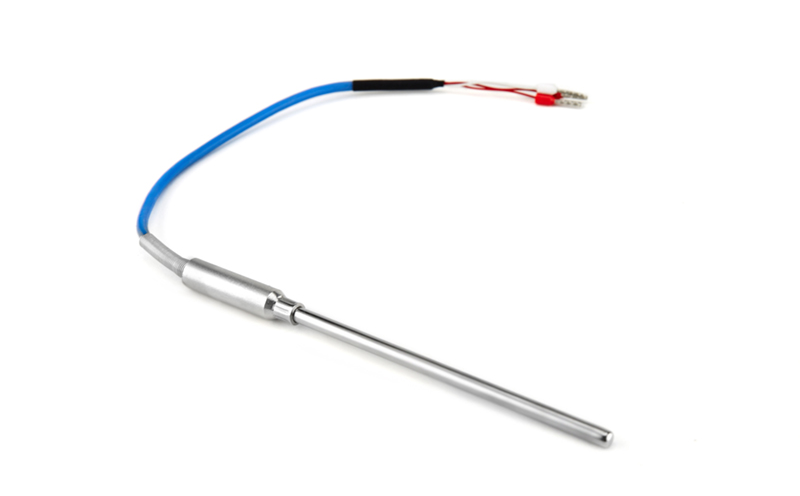

Maintains the production of various RTDs with platinum resistors, meeting or exceeding the requirements of DIN EN 60751. The connected resistance temperature sensor can be integrated or installed in a thermowell or used with a direct process connection. Contact our temperature measurement experts to learn more about industrial temperature sensors and find the right temperature sensor for your application. Tel./WeChat 18717811268 Huang Gong sales@weilianchina.com