Five things to consider when using thermocouple temperature sensor to measure temperature

Five things to consider when using thermocouple temperature sensor to measure temperature

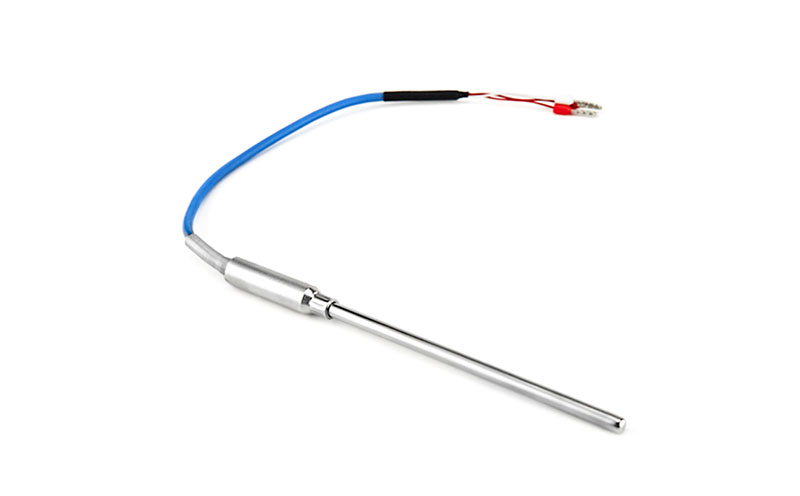

Thermocouple temperature sensor has become a popular temperature measuring equipment because of its versatility, responsiveness, robustness and low cost. To make the most of them, here are five things you should know about industrial thermocouple assemblies.

Thermocouples are the main force in the field of temperature measurement. They are reliable, versatile, durable, inexpensive, and responsive to temperature changes.

There are many calibration types for thermocouple temperature sensors, which are determined by the two metals used for the positive and negative conductors. Two conductors are connected at one end; This is a measurement junction (heat junction). At the other end, the conductor does not contact; This is the reference junction (cold junction). The difference of electromotive force (emf) generated at two nodes can be calibrated to provide fairly accurate temperature readings.

As with any temperature measuring equipment, the main criteria for selecting which industrial thermocouple to use are 1) the operating temperature range and 2) the environment or medium in which these instruments are used. However, there are other considerations to keep in mind when using thermocouple temperature sensor assemblies to measure temperature.

1.reference value

Because the thermocouple uses the difference of electromotive force at two nodes to measure temperature, it gives a relative measurement value rather than an absolute measurement value. The temperature of the cold end must be known to obtain the actual temperature of the hot end. Modern industrial thermocouples measure the ambient temperature of the reference end by inserting a separate sensor in the temperature transmitter, which makes this compensation easier.

2. connect

When connecting the thermocouple sensor, the positive wire and negative wire shall not be interchanged. If it is, the polarity is reversed, and the reading will be incorrect or even negative. Switch wiring is one of the common causes of thermocouple temperature measurement errors. When connecting wires, be sure to observe the specifications of the thermocouple.

NOTE: In many electrical systems, red is used to indicate positive polarity. In the case of thermocouples, the opposite is true, and the red wire is the negative wire.

3. Galvanic isolation

The temperature sensor is installed in the field and grounded, while the measuring instrument is usually located in a separate control room and grounded - sometimes far away from the sensor. The ground potential of the site may be different from that of the control room, resulting in currents and sparks that may damage the instrument. Having a temperature transmitter with current isolation and isolated output will avoid this problem.

Terminal blocks

Terminals have the same temperature rating as the terminal box or field wiring. The screw has a special groove, which can expand the stranded wire and clamp it. It protects wire sizes from 16AWG to 36AWG. Another good feature is the channel, which separates the wires and prevents them from short circuiting to each other.

4. Sensor disconnection monitoring

The purpose of the thermocouple assembly is to give an alarm when the circuit is open. However, under the condition of vibration, the connection in the ceramic terminal may be loose, and even if the circuit itself has no problem, the alarm will be triggered. Ceramic terminal blocks are also easily damaged. Crastin ® The terminal block is provided with a special slot for wires and a clip to firmly fix the connection in place to prevent false alarms. This is why most of the thermocouple modules can be manufactured using terminal blocks.

5. linear

The voltage temperature curve of the thermocouple is not linear. Take the upper and lower limits of inferior transmitters and draw a straight line. This simplification can lead to incorrect readings, depending on which part of the curve you are using. High quality temperature transmitters, such as all the temperature transmitters from Weilian, can linearize the voltage along the curve.

With rich laboratory and field experience, maintenance experts have a thorough understanding of industrial thermocouple systems. Contact them today to learn more about which temperature measurement solution is appropriate for your application. Tel./WeChat 18717811268 Huang Gong sales@weilianchina.com