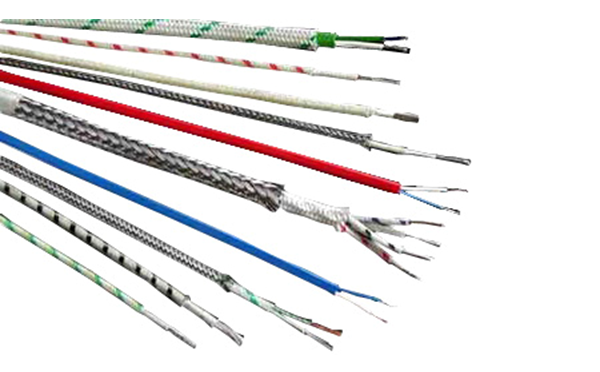

Thermocouple temperature sensor cable and wire

Thermocouple temperature sensor cable and wire

Temperature is one of the most important measurement units in industrial monitoring. It is essential that the temperature be as accurate as possible. Improper management may lead to poor product quality. The perfume with strong fragrance smells ordinary now. The food may have different flavors, or improper temperature management in the medical field may lead to the inability to use donated items, such as blood.

A thermocouple is a commonly used sensor for measuring temperature. The wires and cables of thermocouple and temperature sensor are an important part of the structure, because they complete the circuit between thermocouple and RTD temperature sensor controller. Essentially, this is why the signal is transmitted from the thermocouple to the RTD temperature sensor, which converts the temperature into an accurate reading. The outer insulating layer around the thermocouple wire and some single conductors are color coded for easy identification.

We provide all kinds of temperature sensor wires and cables using various high-performance materials. They are manufactured with the highest quality.

The following is a description of the different materials used in thermocouple wires and cables and the applications they can be used for.

Synthetic cable synthetic fiber——These are made of flexible ceramic fiber yarn, which can withstand high temperatures. The insulation layer covers the sheath and single conductor.

There are a number of applications for using these cables, including:

● Heat treatment

● Steel and aluminum plants

● Manufacturing of glass, ceramics and bricks

● Alternative bead thermocouples

● Soaking tank

glass fibre- The whole sheath and single conductor are protected by glass fiber braid. In terms of insulation, high-temperature resin is impregnated into the cable.

Suitable applications of fiberglass wires and cables to be used include, but are not limited to:

● Steel and aluminum plants

● Heat treatment

● Foundry

● Glass, ceramics and brick factories

● Plastic processing equipment

PVC -Each conductor and sheath shall be color coded separately. It is a relatively cheap insulator. Because these cables are made of PVC, they can be easily stripped and separated, making them flexible and easy to assemble. The wires are also produced in multiple pairs of structures, including copper drain wires. This means that each pair of conductors is individually wrapped with aluminum tape.

Applications well suited for PVC wire and cable include:

● Laboratory

● Industrial equipment testing

● Automobile

● Test facilities

FEP/PFA/PTFE——Each single conductor and outer sheath shall be layered with FEP/PFA/PTFE. It is well known that these wires have excellent moisture resistance, chemical resistance and abrasion resistance.

Applications suitable for using FEP/PFA/PTFE wires include:

● Industrial equipment testing

● Power plant

● Oil plants

● Field heat treatment

adhesive tape- TFE tape is applied to each conductor, and then they are hot fused, and then the tape is applied to the conductor forming the entire sheath. Hot melt tape makes the cable structure a difficult assembly. These wires have excellent moisture resistance, chemical resistance and abrasion resistance.

Ribbon wires and cables are suitable for many applications, including:

● Aircraft composite bonding

● Power plant

● Kiln

● Oil plants

● Glass, ceramics and brick factories

Tel./WeChat 18717811268 Huang Gong Email sales@weilianchina.com