Why is temperature measurement important?

Temperature is usually a key factor in manufacturing and one of the most widely measured variables in industrial processing.

It is used for various industries such as combustion, dryness, refrigeration, burning, heat treatment, calibration, material testing and squeezing, including oil and natural gas, power, oil refining, petrochemical, pharmaceutical, food production, etc.

In some processes, even small measurement errors may be destructive and usually cost high. In addition, keeping the process at the best temperature can bring higher profitability.

The resistor temperature detector (RTD) is considered one of the most accurate temperature sensors. In addition to providing very good accuracy, they also provide excellent stability, repetitiveness, and high antipity to electrical noise. This means that the RTD temperature sensor is very suitable for applications in the process and industrial automation environment, especially around the motor, generator and other high -voltage equipment.

What is a resistor temperature detector?

The resistor temperature detector (RTD) is a temperature sensor containing the resistor, and the resistance value changes with temperature; then it can be associated to provide temperature reading.

The most commonly made of platinum (PT) detectors, because it follows a very linear resistance-temperature relationship in a large temperature range.

They are also called platinum resistance temperature meters (PRT). The PRT temperature sensor can be a flat film for low temperature applications or a winding of higher temperature applications.

RTD PT100 temperature sensor is the most common. The resistance at 0 ° C is 100 ohm, while the resistance of the PT1000 temperature sensor at 0 ° C is 1,000 ohm. Because the PT1000 has higher resolution, they are considered more accurate because the sensitivity or uncertainty of the basic 2 -line sensor is reduced, but the use of 3 or 4 -line RTD temperature sensors can further reduce this uncertainty ( See the RTD temperature sensor circuit below).

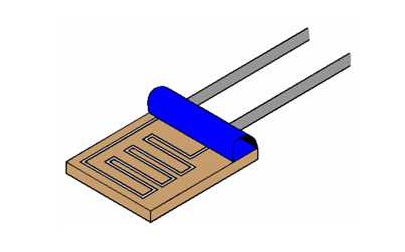

1. Flat -membrane detector

The flat film detector is made by placing a layer of fine platinum silk on the ceramic substrate. The component is then applied to epoxy resin or glass to provide protection. They are cheap alternatives of winding detectors, which have fast response time, but compared with the winding detector, their stability is poor and the temperature range is low.

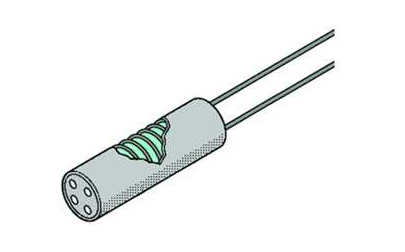

2. Wind -up detector

The winding detector is composed of a section of a thin plate wrapped on the ceramic or glass core. They are relatively fragile and are usually equipped with a cover to provide protection. Compared with flat film detectors, they have higher accuracy within a wider temperature range, but they are more expensive.

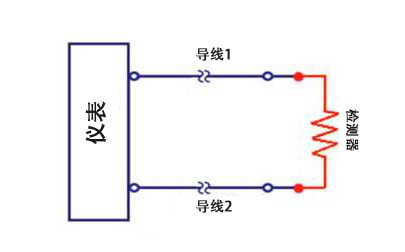

RTD temperature sensor circuit

The RTD temperature sensor not only contains one component; this component is only part of the circuit, which consists of at least two and up to four leaders and arbitrary number of connectors and attachments. Circuit configuration may depend on many factors. Including:

• The distance between the induction area and the instrument

• The temperature in the sensor of the entire length of the sensor

• Connection premiere

• Current wiring configuration, for example, 4 -line sensors will not be compatible with 3 line configuration

2 Line RTD temperature sensor , the most inaccurate among the three types of circuit types, because it cannot be calculated or eliminated the lead resistance between the detector and the read number. This will cause uncertainty of reading, so these sensors are usually used only with short -drawing, and in this case, accuracy is not very important. 2 Line PT1000S can be used to reduce sensitivity and uncertainty, but it still cannot provide truly accurate reading.

3 line RTD temperature sensor is the most commonly used RTD temperature sensor. Suppose that all three leads are the same, and the third lead is calculated to calculate the average lead resistance of the entire circuit and delete it from the sensor measurement. This makes the 3 -line RTD temperature sensor more accurate than the 2 -line RTD temperature sensor, but it is not as accurate as the 4 -line configuration. However, in the circuit with a long lead, the distance between the detector and the reading is very long, and the 3 -line structure can be used.

4 -line RTD temperature sensor is used to require applications close to accuracy. In the 4 -line RTD temperature sensor, the actual resistance in each lead can be measured and eliminated, leaving the precise resistance of the detector. The working principle of the 4 -wire circuit is to use the first two wires to power the circuit, while the 3rd and fourth guide line reads the resistance in each wire to compensate any difference in the wire resistance.