How to connect MICC cables to soft leather cables?

How to connect MICC cables to soft leather cables?

Weilian engineers have been asked countless times, "How to connect MICC cables to soft leather cable ". This process is not common, but we must create a method to help our customers, so we made a toolkit to connect cables together.

MICC cable mineral insulation copper bag cable , commonly known as thermalrmal cable, is an ideal solution for fire prevention. It is a cable made of copper -guided by copper conductivity and copper care.

Soft skin flame retardant cable from a single or multi -stock conductor (copper), from the personal core insulation (polymer) and the external insulation cover (polymer).

We call this connecting MICC cable as Flex cable (soft leather) with single core connection or multi -core connection. If you operate according to the instructions, this will be able to complete the connection, so as to maintain the integrity of the cable circuit under electrical conditions. When ordering parts, you will need the size of the cable to ensure that you receive the correct component.

Ground continuity: When installing the MICC to a flexible connector, you need to ensure that you keep the grounding continuity. Since the MICC sheath is the earth, you will need to be connected to the ground and organize the flying line to the extended Flex cable. We provide the application with a full range of ground clips.

Single -core kit includes:

Copper -plated pressure connection wires/links, glass cloud mother bands, silicon -impregnated glass sleeves/woven belts, and lining adhesive thick wall thermal heating tubes.

Multi -core kit composition is the same as a single -core kit, but each component is multiplied by the required core.

Connect the MICC cable to the steps of the soft leather cable:

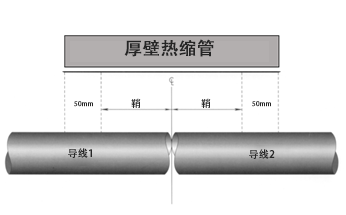

Step 1: Slide the hot tube over one of the cables.

Step 2: It is important to ensure that the two ends are extended by 50 mm at both ends when applying the final heat contraction. The length of the cable sheath to be removed can be calculated like this:

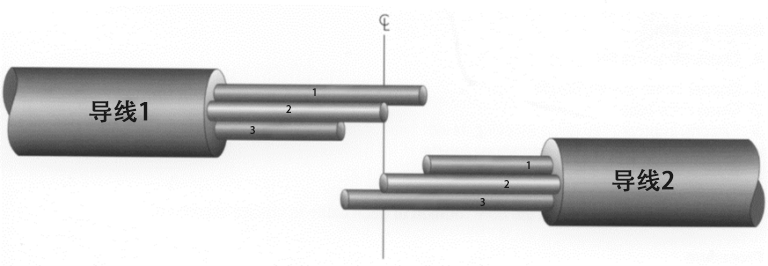

Note: You may need to minimize the diameter of the joints to apply the final thick wall thermal tube. This can be implemented in multi -core cables by staggering the conductor connector.

Step 3: Peel off the insulating layer and glass cloud mother belt from each core of each cable (half of the link length).

Step 4: Slide a silicon resin to each wire core of a cable.

Step 5: Use the provided pressure -connected tie/link to connect the corresponding magnetic core.

Picture

Step 6: Apply a fire -resistant barrier with glass cloud mother. The length of the tape should extend on the insulator is about the link length. When the glass cloud mother belt, the light should be directed at the conductor. Starting from the insulating core opposite the silicone cover, and using 50% overlap application of Yunmu belt. Without destroying the tape, continue to pass through the curl link on the insulation layer. Use a small piece of tape (not provided) to fix the loose end of the tape.

Step 7: Slide the glass woven material on the glass cloud mother tape core. Located in the city center.

Step 8: Slide the heating tube of the lining adhesive to the connector and place it in the middle. The shrinking tube starts from the center and works to the end to avoid air retention.