Different temperature measurement methods

Industrial temperature is a major physical quantity. There are different temperature measurement methods in the industry. The different methods of temperature measurement are:

1. Mechanical method:

mercury in the glass thermometer

This includes a very fine pores, which is connected to a liquid tank at the bottom and sealed at the top. The measured mercury amount is closed. When the thermometer is heated, the expansion ratio of mercury

The glass is much larger, so it is forced to rising in the tube to fix the side.

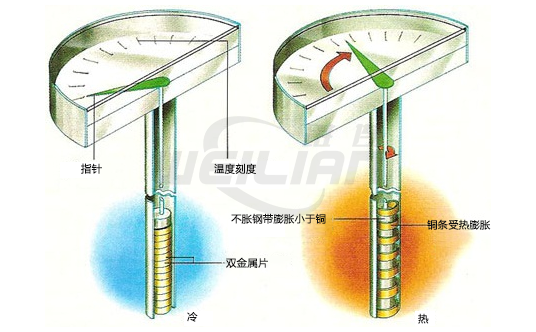

Bimetallic thermometer

Welded the two lines of expansion coefficients together and rolled into the required thickness. The actual movement of dual metals is a fixed flexibility at one end, and the straight metal bars will

Compared with its temperature, it is directly proportional to the square of its length, which is thickened.

Compensation thermometer system:

The provision of compensation is to offset the impact of changes in the environmental temperature. The compensation in the expansion of the expansion of the liquid is composed of the second tube and the spiral element, and both are charged.

The structure of these two components makes the measurement spiral float on a mobile base, and the position of the base is controlled by compensation spiral. The two pipes and spiral tubes match the volume, so

The temperature changes of the instrument shell and the capillary tube will have equal movements from the two spiral tubes. This kind of movement is invalid, so only by changing the motion generated by the bulb temperature can it drive the recording pen.

Elastic temperaturemeter:

This type depends on the increase in the pressure of confirmation gas (constant volume) due to increased temperature. The relationship between temperature and pressure in this system follow Charles's law and can be expressed.

The system is filled under high pressure. Therefore, every time the temperature is elevated, the increase in pressure is greater than the pressure of low filling pressure. Nitrogen is the most used in such systems, because it is chemical

Insert and have a good thermal expansion coefficient.

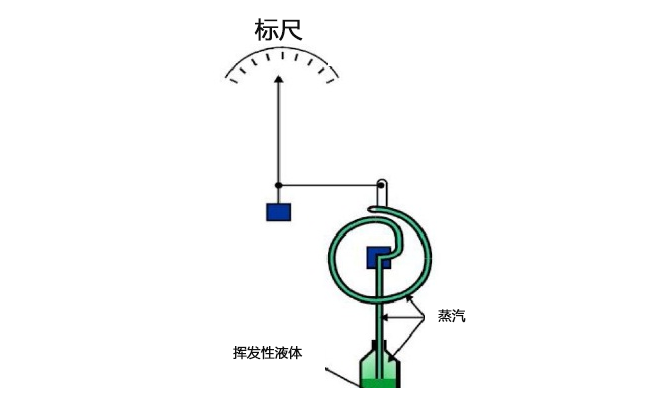

Steam pressure thermometer:

The steam pressure thermometer depends on the steam pressure of the liquid, and the liquid is only partially filled. At low temperature, the steam pressure of the temperature in each unit of temperature increases very small. At higher temperatures,

The steam pressure changes are much larger.

2. Electric temperature testing method

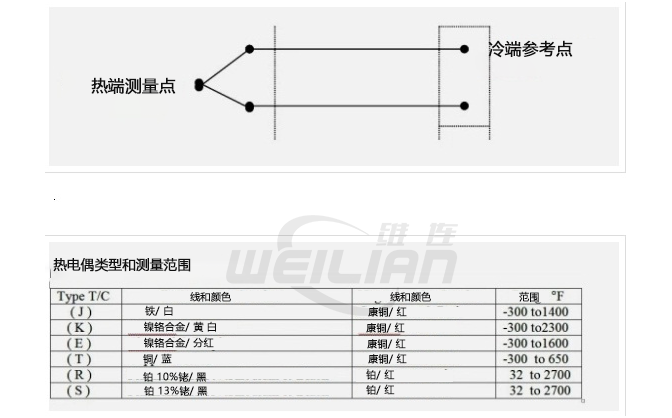

Heat Patriotic

It is a simple device that consists of different metal lines connected by the end. When one in each wire is connected to the measuring instrument, the thermocouple becomes an accurate and sensitive temperature measurement device

Resistance -temperature detector (RTD)

RTD is usually used for accurate temperature measurement. It consists of five wires that are wrapped on the insulators and packed in metal. resistance thermometer < /u> Most of the shentons are similar to dual metal thermometers

The sheath of the bulb.

Principle: "The resistance increases with the temperature increase"

RT, = Ro (1 + α t)

RT, = measured temperature resistance.

RO. = Zero temperature resistance.

α = Co. Turn off the heat (expansion).

T = temperature to be measured.

These metals have positive expansion temperature coefficients . As a result, the resistance increases with the rise of temperature.

Types of materials used: (1) Platinum (2) Nickel

These metals have a positive temperature expansion coefficient. As a result, the resistance increases with the rise of temperature.

Calculation of resistance or PT100.

RO = 100

X platinum = 0.00385 /c.

Calculate the resistance when 100'c.

R100 = 100 [1+ (38.5 x 10 4 x 100)]

= 100 + (100 x 0.385)

R100 = 138.5

Resistance at 100'c = 138.5