Reference information of thermocouple technology

If your question is not answered here, you can use Online contact us or call our technical engineer 18717811268 Huang Gong.

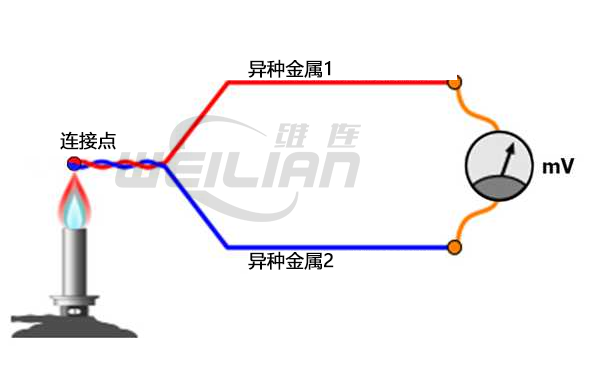

1. What is thermocouple (how do they work)?

The thermocouple is a sensor for measuring temperature in many processes. The thermocouple is composed of two lines made of different metals, and one end of them is fixed together to form a connection point. When the knot experiences temperature changes, the voltage is generated, and then the voltage can be measured and it is used as a reference of temperature. This is also known as the "Sebeck Effect".

2. Different thermocouple types

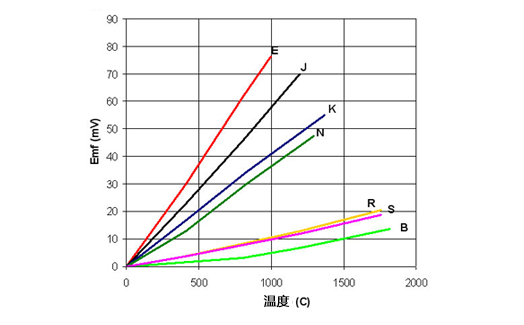

The thermocouple has different metal combinations. Each metal has its unique characteristics in terms of temperature range, durability, vibration resistance, chemical resistance and application compatibility.

• Aquarius thermocouple or K, J, T and E is relatively low, so it is the most popular thermocouple, which are usually used for extensive and low temperature applications.

• precious metal thermocouples or R, S and B have greater resistance than cheap metal thermocouples, but they have platinum conductors, so they are much more expensive. They are usually used in high temperature applications.

The following figure shows the characteristics of all major cheap metals and Nobel hotpot types and the relationship between temperature and MV output. This indicates that the thermocouple sensor has a relatively linear output.

3. Thermocouple structure

The thermocouple structure is composed of two conductors that welded together at the measurement point and insulated along the length. It usually has an external protective sheath.

PVC, Silicon Rubber, FEP or PTFE insulator and other materials are most commonly used in applications of up to 250 ° C. Glass fiber or ceramics is used for temperature higher than 250 ° C. For the medium temperature range (400 to 1200 ° C), the thermocouple protection cover is usually metal, such as stainless steel or alloy 600, and can be a pocket for mechanical processing, which aims to adapt to a specific process. Used at high temperatures that are usually higher than 1100 ° C. Ceramics cover.

Compared with the sensor, the selection and design of protective cover usually requires more considerations, because they are more expensive and must provide protection from chemical or physical attacks. Sheaths are usually customized because they are designed specifically to adapt to specific processes or applications.

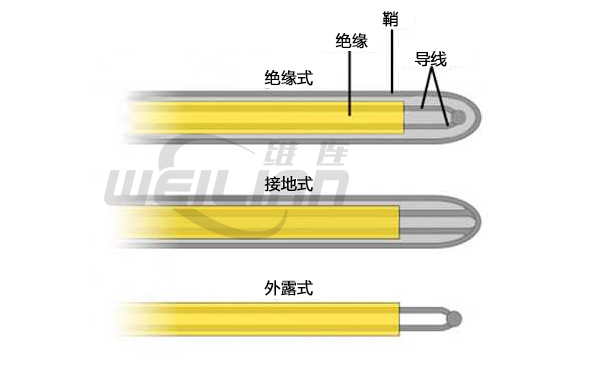

4. Thermal puppet knot

The thermocouple probe can provide one of three main connection types: grounding, insulation, or exposure, as shown in the figure below.

• In the unscated or insulated probe, the thermocouple node isolates from the outer cover material, which will reduce any electrical interference and provide stable reading, but it will cause the response time to slow down, and it is usually more expensive than the alternative of ground or exposure. Essence

• At the tip of the grounded thermocouple, the thermoelectric puppet knot is a physical connection and a component of the outer sheath. Due to the good heat transfer from the sheath to the thermal puppet, the response time is faster than the unscrupulous knot; however, the reading may sometimes unstable.

• An exposed contact either has no outer sleeve or the thermocouple contact extends to the outer cover. It is not recommended to use them in a corrosive environment, but provides very fast response time at low cost in the correct application.

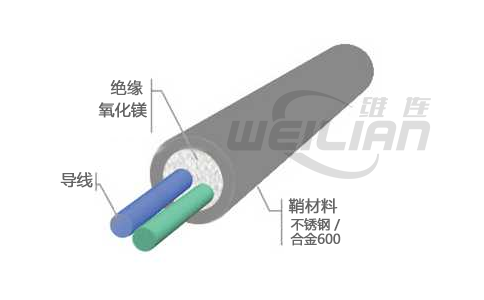

5. Mineral insulation thermal power puppet

Mineral insulating thermal power puppet consists of an external metal sheath to accommodate the thermocouple conductor; then fills highly compacted magnesium oxide powder in the protective cover to prevent any point contacts outside the fixed connection point. This structure allows the protective cover to bend or form according to the needs of the user, but maintains rigidity during use. The entire component is sealed, providing a comprehensive protection for the conductor exempt from the impact of the operating environment.

Provide 2 cores (single cores) or 4 cores (dual -core) and a series of outer sleeve materials, including level 25/20 (310) stainless steel (corrosion resistance, suitable for sulfur -containing environment), alloy 600 (severe corrosion The environment is high -temperature) and NicroBel D (recommended to be used with the K -type and N -type hot -electric puppets, with good high temperature intensity and excellent performance in oxidation, carburizing, restoring and vacuum environment).

6A. Why use mineral insulated thermal power puppets?

Fast response

The high density of mineral powder promotes the rapid heat transfer between the conductor and the sheath.

High flexibility

Mineral insulation Cable is very flexible, which can form a variety of angles and shapes to ensure the perfect fit application. This also allows easy installation in a difficult place.

Wide temperature

Mineral insulation sensors are a popular choice because they have a very wide temperature range. Fire fire and expose at a temperature that is much higher than synthetic sheath cables.

Life life

The structure of the cable guarantees a longer conductor life. Because the shestons and insulation powder protect them, they can withstand environmental conditions such as corrosion.

6b. Mineral insulation thermal electric puppets of the hot electric puppet

Mineral insulating thermal power puppets can be bent into many complex shapes. However, there is a minimum bending radius, which is three times the diameter of the cable.

The above figure shows a MI cable with a diameter of 3 mm at its smallest bending. To calculate the minimum bending radius, just multiply the cable diameter by 3, so the minimum curved inner radius of the 3mm cable must be 3 x 3 = 9mm.

Calculate the length of the week (18 mm in Figure 1), and only need to multiply the radius (9 mm in Figure 1) 2. This is the minimum size of the MI cable as the required shape.

7. What are the use of different types of thermos?

Thermocouple

We only use 1 type of material to create the K -type, T, J, N, R, and B industrial temperature measurement for the IEC584 standard. The thermocouple can be as simple as the naked line sensor, or it can also be a pure platinum ceramic cover R -shaped component for high -temperature applications.

Line -like hot mobility

The wire thermocouple is a very simple sensor. They provide very fast response time at low cost, but because most of the wire sensors are "exposed", they are usually not suitable for use in industrial applications. Line -shaped thermocouple is an ideal choice for temperature measurement applications, such as testing and measurement, temperature mapping, and OEM applications. If you are looking for a low -cost basic sensor for general purposes, line -shaped thermocouples are a good starting point.

Overcoming thermocouple

This series of probes have a protective processing cover for more industrial applications, including furnaces, heat treatment, machinery and water treatment. They can be used for the nodes you choose: grounding, insulation or exposure (depending on the requirements), with extensive end connections, such as lead, transmitter , plugs, or industrial head components to adapt to various types Application

Surface thermal puppet

A series of surface thermocouples used for permanent or temporary temperature measurement can be used for many applications, including R & D, HVAC, pipeline, air conditioning, and temperature surveying. Surface thermocouples are very popular because they can be used for various types of surfaces, including unevenness and round surfaces. They are also very easy to use, and they are usually very easy to replace and position.

GM

Although many of our sensors have more than one purpose, this series of sensors are the most diverse. They include a bayonet -type armocouples for the plastic industry, a load probe for pharmaceutical and high -voltage kettle applications. And various thermocouples, such as padding, blades and bolt probes used for general temperature measurement.

Mineral insulation thermal electric puppet

Our standard mineral insulation thermal puppet series is shown below, but if you need to meet the products you require, please contact us because we are also produced according to orders. Mineral insulating thermal power puppets are strong and flexible, which can make a long length and wide diameter range.

Handheld hot electric puppet

Weilian manufacture a variety of handheld thermocouple sensors, which is used with digital handheld thermometer to measure the surface, air or insert temperature measurement in various applications, such as food, catering, drinks, refrigerated facilities or environmental calibration types K, J and T. We also produce a handheld PT100 RTD, which can provide customized products according to the requirements.

8. Select 7 steps of the thermocouple

When choosing a suitable thermocouple sensor, many factors need to be considered.

Customers often come to us with drawings, specifications, photos, or just what they want, we usually take it from there.

By raising a few questions, we can usually determine what thermocouple you want. However, in many cases, our customers can only purchase projects from third -party customers or engineers in the organization.

Or, you may just have a new application that requires measuring temperature, and you have never purchased such products. Again, we can help.

Below we will discuss 7 steps you need to consider in order to choose the appropriate thermocouple for your application.

1. Calibration

Do you know the type of thermocouple you need? For example, type K, T or J. If not, this is the first thing you need to consider. No matter where you connect the thermocouple, it is usually determined. In addition, this will determine the accuracy of the thermocouple.

2. Application

What are you measured? Is thermocouple measure liquid, surface or gas? Does it must be located in a pipe or container or part of the machine or equipment?

3. Environment

What are the aspects need to be considered? For example, does it need chemical resistance, IP grade, ATEX certification, food use, high vibration?

4. Location

How to fix the thermocouple in the application, such as; wall -mounted, handheld, outdoor or indoor. Does it need accessories to be fixed?

5. Work scope

(for example, 0-1000 degrees Celsius) This is the main restrictions when choosing a thermocouple, because it determines the materials used in the structure and the calibration types in many cases.

6. Physical precautions

What are the requirements for length, diameter and size? Does it need to bend or very long?

7. Connection with the application

What is the connection of thermocouple connection? Do I need a wiring terminal, connector, wire or transmitter?

If you can answer these questions, then you should be able to determine the thermocouple you want. To help you, we have an easy -to -use questionnaire that can be completed and returned to us, or you can simply call or send an email to ask us your question, we will help you at any time.

9. Comparison of RTD and thermocouple < /strong>

A practical guide can help you choose the right product for your application.