This article introduces how to protect the contact temperature sensor from the influence of the extreme process environment in the process of modern high -temperature industry.

The contact type temperature measurement method is still the most effective method for measuring temperature, which can control the industrial production process. However, its success depends to a large extent on the degree of protection of sensing elements in the process environment.

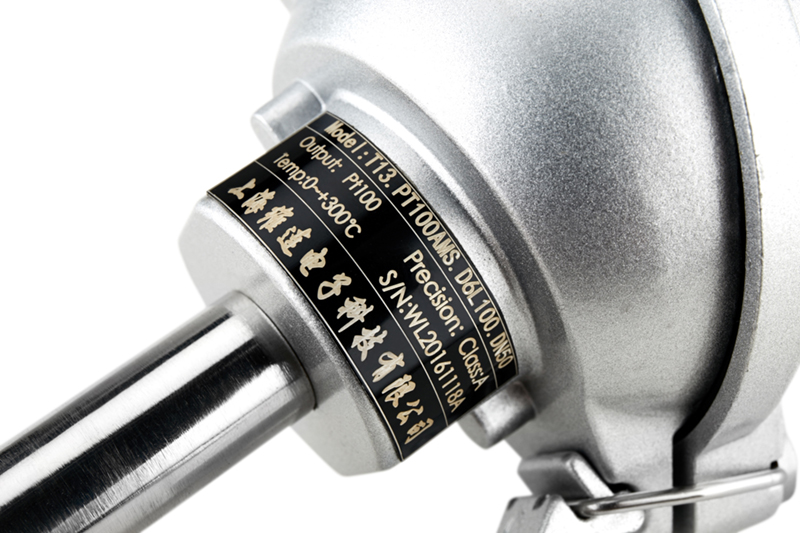

The choice of thermocouple temperature sensor

For processes with a temperature of more than 1,000 degrees Celsius, the use of platinum -based thermocouple (R, S, and B) is a common approach. With the improvement of mineral insulation thermal power puppets, especially the Nilbeel cover -type N mineral insulated thermostat performance, the industrial world has provided an alternative to the platinum -based thermocouple temperature sensor from 1200 ° C to 1250 ° C.

Vio to 1250 degrees Celsius

Once the temperature exceeds 1250 degrees Celsius, the only option of industrial contact thermometer is to use the platinum base thermal power puppet. Usually, they are installed in ceramic sheaths made of re -crystal aluminum. In a place with a high temperature, the common practice in many industries is to use aluminum porcelain, because the cost of protective cover and insulators is much lower than the cost of heavy crystal aluminum. This method is not recommended, because aluminum porcelain contains free silica, which will poison the platinum heat puppet. Aluminum porcelain also contains a large number of free NA2O3, plus a little reducing agent, which will make platinum and aluminum porcelain interaction. It should also be noted that the thermal guidance of heavy crystal alumina is much larger than that of aluminum porcelain, which makes the thermocouple response to temperature changes faster.

Promote only the use of aluminum alumina to ensure the maximum service life and performance of the standard ceramic cover thermocouple.

Ceramic hotcoulette protective cover cannot withstand the process environment in many applications. Due to the characteristics of its structure, the aluminum aluminum is very prone to heat shocks and must be preheated before installation.

Silicon carbide has excellent corrosion resistance and chemical corrosion. The use of silicon carbide as a heating element also confirms the applicability of its standard form in high temperature applications. Because it contains free silica, it is easily attacked in a strong oxidation environment.

With the development of alloy sintering silicon carbide materials, a silicon carbide material that does not contain free silicon dioxide has excellent chemical resistance in the reduction and oxidation environment.

The characteristics of silicate alloys make it ideal materials for the thermocouple protective cover:

High temperature performance reaches 1650 ° C.

High thermal conductivity; many times the heavy crystal alumina

The heat shock resistance is more than ten times the re -crystallized alumina

Undefeated at 31MPa

wear resistance: 50%higher than tungsten carbide hardness

High -intensity and high elastic modulus

Excellent creep resistance

The areas that have been successfully applied include: mining engineering, non -ferrous metal melting and refining, high -temperature process furnace, chemical incineration furnace, recycling furnace and corrosive chemical treatment process. Its high temperature capacity makes it extremely effective in the coal processing industry, including gasification at temperatures above 1600 ° C.

Metal Ceramics (LT-1 or LT-1)

Another protective cover is metal ceramics, a composite material composed of chromium and alumina. The combination of this metal and ceramics has excellent antioxidant properties above 1200 ° C, and can resist the wetting of many metals and alloys.

The high thermal conductivity makes it better than ceramics in thermal impact capacity, but it should still be preheated before immersion in melt metal.

It is recommended to use in the following process:

Mild copper, brass, zinc and lead

Extremely good in the atmosphere containing SO, SO3.

窑 <<

Black furnace top and ring tube

Gas and Ethylene Cracking atmosphere

fuel furnace room

Because chromium phase becomes easy to respond at high temperatures, metal ceramics are not recommended for carburizing or nitride atmosphere, nor are it recommended in aluminum melts. Its maximum continuous temperature level is 1400 ° C.

Although there may not be an ideal protective cover for each process environment, Victoria will choose the most suitable thermocouple/protective set combination after analyzing the process conditions to the most suitable needs of users. By doing this, customers can rest assured, the most cost -effective solutions, their temperature sensing problems have been applied.

How to protect the thermocouple temperature sensor in high temperature environments

How to protect the thermocouple temperature sensor in high temperature environments