How does the RTD temperature sensor work

How does the RTD temperature sensor work What is RTD temperature sensor?

The resistor -type temperature detector, also known as RTD or resistance thermometer, is a temperature sensor. RTD includes sensing elements, connecting sensor elements to the wires of the measuring instrument, and brackets used to locate sensor elements in this process.

How do they work?

The design of the RTD temperature sensor to ensure accurate and repeated temperature and resistance characteristics. The type of material for the RTD temperature sensor structure will determine the temperature limit that the RTD temperature sensor can be exposed to. The sensor element in the RTD temperature sensor is a resistor that changes the resistance value with the change of temperature. The resistance occurs with a predictable rate with changes in temperature, and can provide the temperature of the processing material by measuring.

The sensor element in the resistance temperature sensor usually contains a coil or a substrate with a platinum film. The allowable resistance to the extension line connected to the sending element is measured at the distance from the measured process or material. A protective cover (usually stainless steel) is equipped with sensor elements. Platinum is a typical material choice in a thermal resistance, because it allows a larger temperature range, it is a more stable material. If a lower temperature range is required, nickel and copper can also be used for RTD temperature sensor structure.

Table I. The temperature range of the summary is each material.

| Table 1: Sensitive element materials and temperature limit |

| Material |

Available temperature range |

| Platinum |

- 200 degrees Celsius to 850 degrees |

| Nickel |

- 100 degrees Celsius to 315 degrees |

| Copper |

Joint 75 degrees to 150 degrees Celsius |

The wire insulation type used in the resistance thermometer also affects the resistance temperature. Table 2A. Refers to the most commonly used wires and insulation materials and its temperature limit. Table 2B. Refers to the wires to control the instrument or the temperature limit of the connection component to the control instrument or the temperature limit. The typical choice of wire insulation includes nickel, nickel alloy, silver -plated copper or nickel -plated copper.

| Table 2A: Connect temperature limit-structure |

| Wire/insulation material |

Maximum use temperature |

| Nickel -plated copper/TFE polytetrafluoroethylene insulation |

250 degrees Celsius |

| Solid nickel wire |

650oC |

| Solid copper thread |

300oC |

| Table 2B: Connection The temperature limit-extension |

| Wire/insulation material |

Maximum use temperature |

| Tin -plated copper/polyvinyl chloride insulation |

105 degrees Celsius |

| Silver -plated copper/polyfront fluoride insulation |

25 degrees Celsius |

| Silver -plated copper/TFE polytetrafluoroethylene insulation |

250 degrees Celsius |

| Nickel -plated copper/TFE polytetrafluoroethylene insulation |

250 degrees Celsius |

| Nickel -plated copper/glass fiber insulation material |

480 degrees Celsius |

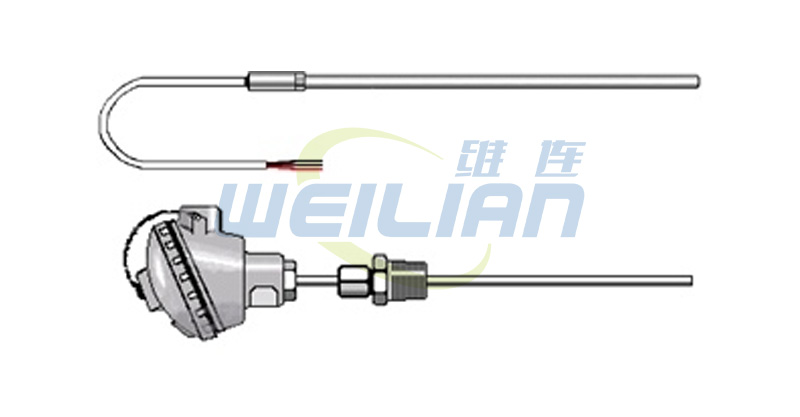

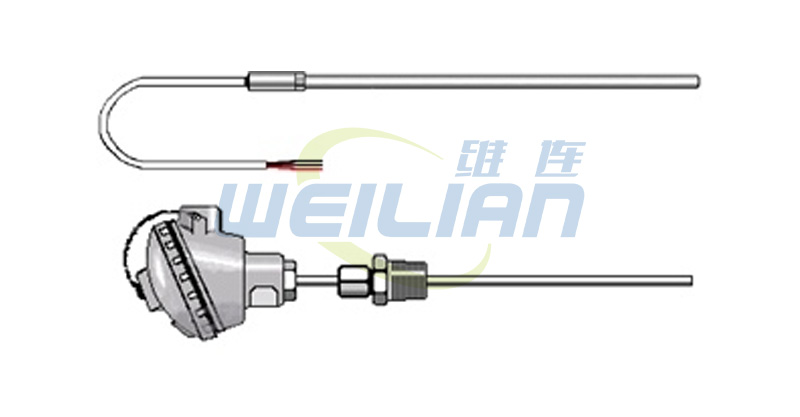

There are two most commonly used methods for RTD temperature sensor structure. The most common is to put RTD components and connecting wires into a closed metal tube. The tube is equipped with vibration reduction and/or heat transfer materials. In most cases, alumina powder is used, and the opening of the mouth of silicon resin, epoxy resin or ceramic cement is used.

Another construction method is to use the mineral insulation metal sheath (MIMS) cable. RTD components insert a drilling hole and connect to the nickel or copper wires that are connected to the magnesium oxide (MGO) insulation. The end is also closed with magnesium oxide insulation and welding. The other end is sealed before the extension line connection. Once the temperature range and application are determined, Wilian will choose the most suitable material and method to build the thermal resistance temperature sensor.

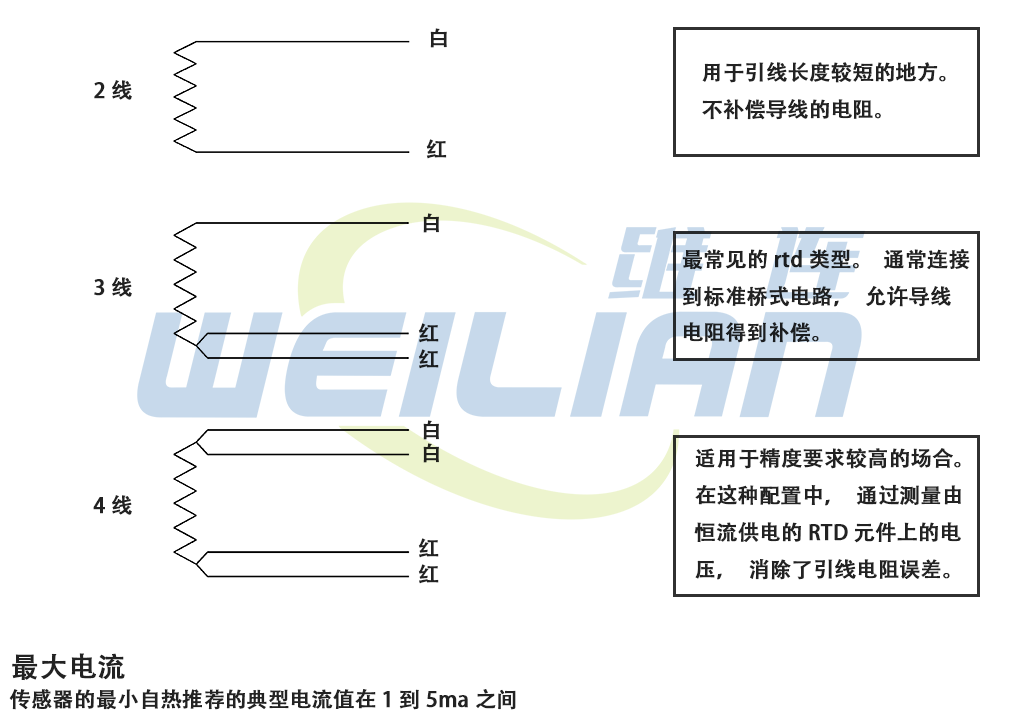

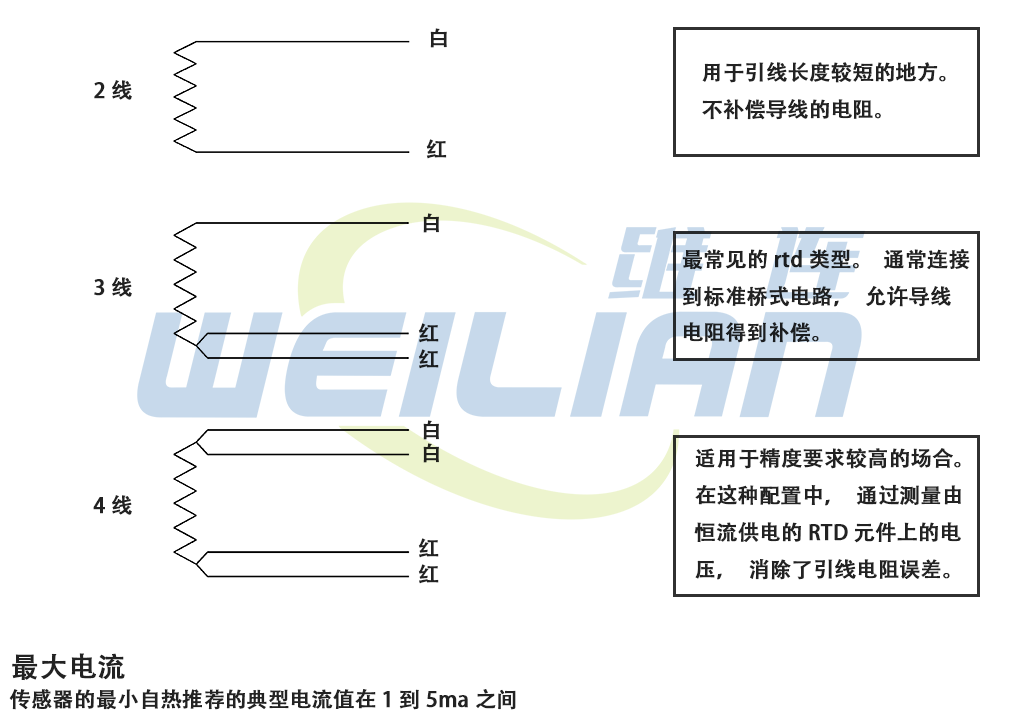

2, 3 or 4 line configuration

The dual -line structure is the least accurate. 2 Line RTDS is often used with short -drawing, or in places that do not need accuracy. The three -line structure is the most popular choice, industrial applications, and the four -line structure is used in the laboratory, and the close accuracy is essential.

When choosing the correct RTD temperature sensor for your needs, there are many options to consider:

• Rating temperature

• Tolerance, accuracy and interchangeability

• Time response

• The distance from control or measurement device

• RTD temperature sensor is suitable for a variety of industries, including air regulation and refrigeration, stoves and grills, textile production, food processing, plastic, petrochemical, and temperature of air, gas and liquid. When using the resistor temperature timing, the accuracy and stability you need, the accuracy must be extended to a wide temperature range.

How does the RTD temperature sensor work

How does the RTD temperature sensor work