NTC thermistor temperature sensor to ensure the safety of lithium ion batteries

NTC thermistor temperature sensor to ensure the safety of lithium ion batteries

NTC thermistor temperature sensor is a key component of lithium ion battery charging and safety. They provide the critical temperature data required for the best state during the charging cycle. Careful management of temperature during the charging process can extend the life of the battery and avoid the risk of lithium -ion batteries.

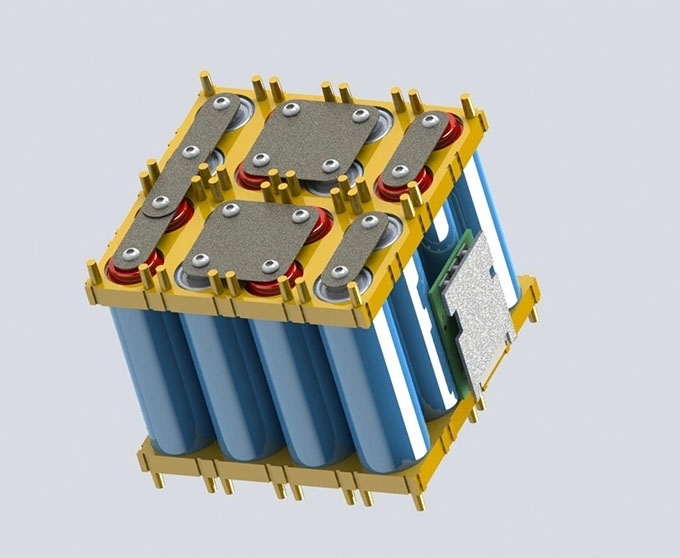

Lithium ion battery provides motivation for green energy

Because lithium ion batteries are light weight and high energy density, it is specifically used for consumer electronics. At present, lithium -ion batteries are replacing lead -acid batteries in energy storage system (ESS), photovoltaic solar (PV) and electric vehicles (PEV). Unlike previous battery technology, lithium -ion batteries do not produce "memory" when charging or discharging partially and can be completely discharged and charged for hundreds of times without lowering performance. This makes them particularly suitable for the application of green energy.

Lithium ion battery-home solar energy storage

Lithium -ion battery charging

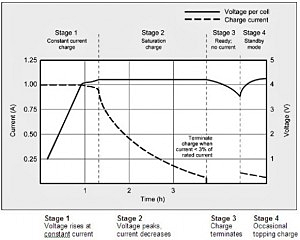

This battery comprehensive chart illustrates the four different stages of the charging of lithium ion batteries. It shows the current and voltage relationship in the entire charging cycle.

1. The current is kept at constant when the voltage rises to the maximum set value.

2. The saturation voltage is maintained at the maximum set value, and over time, the charging current is reduced.

3. Are you ready? When the charging current drops to 3%of the battery rated output current, the charging voltage is turned off.

4. The feed only needs this stage only when the battery is in the standby mode for a long time.

The charge balance, although not one of the four charging stages, is necessary for safe and effective use of multi -battery lithium -ion batteries. Also known as charging balancing, it ensures that each battery unit keeps synchronized during the charging process.

Restricted voltage and current

Lithium -ion battery charging requires voltage and restrictions in the pre -charging stage, limiting charging current, and allowing the charging voltage to rise. The number of charging hours is mainly determined by the maximum rated current of the battery. As the charging proceeds, the increased voltage is limited to the predetermined settings between 4.1V and 4.3V per battery, which depends on the chemical composition of a specific lithium ion battery.

Early nickel -based batteries require the voltage limit of each battery to 4.1V, while each battery of cobalt batteries, manganese batteries and aluminum batteries cannot exceed 4.2V. The highest capacity lithium ion battery is only charged by 4.3V per battery.

In the saturated stage, the voltage is kept at the maximum setting value of these pre -charging. The charging current dropped slowly and then dropped rapidly. When the charging current drops to 3%of the battery rated ampel hours, the charging is over, and the battery can be used.

The feeding is different from the dripping charging. Lithium -ion batteries maintain a good charging state in an idle state, with few internal discharge, but may need to be "charged" after a long time. It is not recommended to charge.

In order to ensure stability, the voltage and current are carefully controlled during the charging cycle. Among them, the control charging voltage is the most important to manage the temperature of the battery.