Where should I install the heat suite? Best Practice Guide

Where should I install the heat suite? Best Practice Guide

When installing the thermocouple temperature sensor sleeve in the pipeline, users must first answer the problems about their location, quantity, valve stem length, distance between each other, and the impact on the process medium.

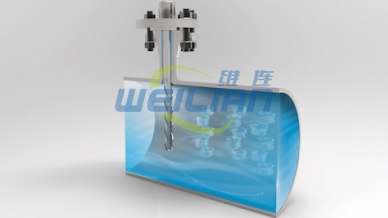

Thermal tube is a high -efficiency equipment used to protect the temperature sensor (such as the resistor thermometer (RTD) temperature sensor) from the process medium in the pipeline. They are usually perpendicular to the flow insertion and use the flange to connect. However, the placement and installation of thermocouple sleeve is an art. Some of the most common questions I have received:

● What is the ideal insertion length of the heat suite?

● How far should the thermal puppet sleeve should be separated from each other?

● Where should the heat suite be installed in the elbow?

Here are some answers about the selection, placement and installation of the thermal sleeve.

1. The insertion length of the heat suite

The correct length of the thermocouple sleeve depends to a large extent on the diameter of the pipe or pipe. A rule of experience is to insert the thermocouple jacket into two -thirds of the fluid flow. Other guidelines recommend that the insertion length is 10 times or at least 50 mm to the tip diameter of the hot sleeve.

The spiral stripes on the thermocouple sleeve will destroy the vortex and make them too weak without causing mechanical fatigue.

The goal is to balance the possibility of mechanical failure and the possibility of sensing errors. On the one hand, the longer the insertion length, the greater the possibility of the heat suite bending or mechanical fatigue due to the speed of the process medium. On the other hand, the shorter the insertion length. Due to the poor heat transfer, the more likely the user to see the unreliable results. In short, the heat suite does not have a perfect rod length, but a goal of a balanced result.

One way to reduce vibration and mechanical fatigue is to use a specially designed thermocouple sleeve. This thermal sleeve has spiral plates to inhibit vibration caused by vortex. Strict durability test proves the effectiveness of this design as a vortex broken device.

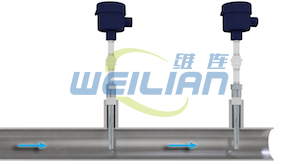

2. Multi -thermal suite installation

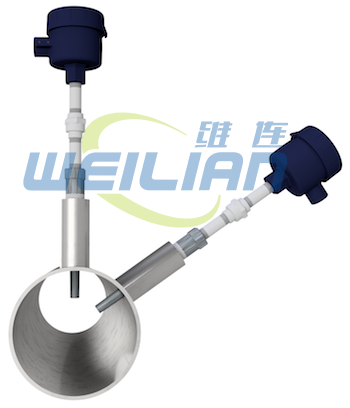

In most cases, a thermocouple sleeve with a temperature sensor is enough for a pipeline. However, some processes need to install multiple thermocouple sleeves in one area. The key to installing multiple heat suite is to minimize their influence on each other, and at the same time provide consistent mobile characteristics in the process. There are two ways to do this:

The heat suite installed with partial angle

The offset angle -In this case, the two thermocouple jackets are installed in the same position, but they are shifted with each other. By placing them in the same position, they will not be affected by the upstream or downstream installed in series. They should be installed at a minimum angle to facilitate installation and disassembly. In addition, the tip of the thermocouple sleeve should stay away from each other to avoid affecting each other's reading.

Thermal suite in embedded installation

Internal Union -In order to ensure the stratum flow in the process, the distance between the thermocouple sleeve can be ranging from 10 to 100 times the diameter of the pipeline, and the range is really wide! Multi -factor placing in the embedded thermocouple sleeve will affect multiple factors, but conservative estimates are 25 times that of the pipeline size. For example, in a pipeline with a diameter of 4 100 mm, the distance between the installation of the thermocouple sleeve is about 2.5 meters: 4 "x 25 = 100" = 8.33 '.

3. Equal installation

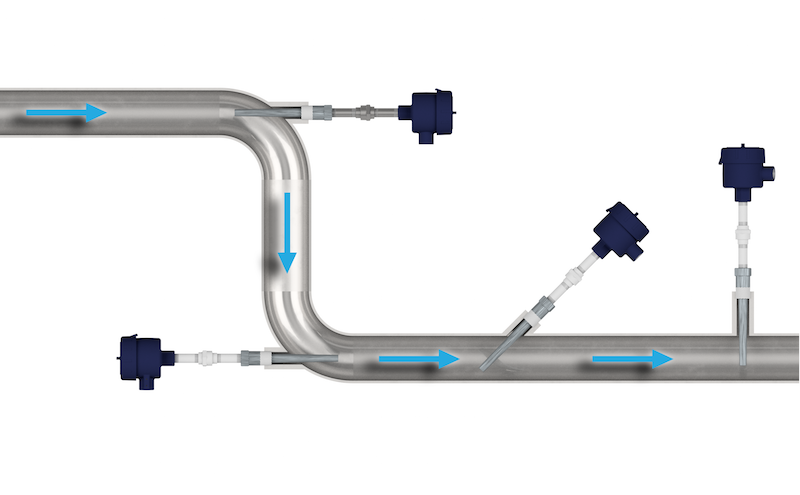

Installed in the bending pipe allows the inductive area of the heat suite to place the central line of the pipeline to ensure the best location of the measurement process. There are two different thermal tube installation positions in the elbow::

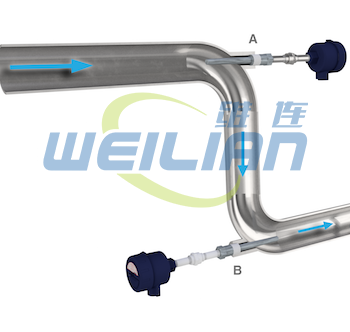

Installation of heat suite in the elbow: a. Facing upstream, b. Facing downstream

Facing the upstream of the upstream -the tip of the hot -sleeve tube (such as the temperature sensing area) is located in any effect (such as mixing or spinning) of the bending pipe. Although TR30's curved momentum calculation exceeds the scope of this standard, many users prefer this elbow installation rather than "facing downstream".

Facing downstream -the tip of the thermocouple sleeve is on the downstream of the elbow, which means that it may be affected by any hybrid or vortex caused by the elbow. The advantage of performing the calculation of the tube tail flow frequency is that the conservative method is adopted downstream and assumed that it is vertically installed.

Other precautions for the installation of heat suite installation

When installing these protective accessories, the length, spacing and location of the heat suite are the main consideration, but not the only consideration. Users should also keep these other factors:

● Pipeline size -from small (5 cm to 10 cm) to large (> 1.5 meters) ranging

● Process media -whether it is gas or liquid

● Two -phase flow -such as gas and liquid, two different liquids, a liquid and solid particles, or a gas and solid particles

● Flow type-stable or pulsation

● The distance from other measuring instruments or accessories

Select the correct type, size and location for the heat suite. Many factors need to be considered. For more information about which connector is suitable for your specific processes and requirements, or which location should be installed in the pipeline, please contact Weilen temperature measurement experts. Phone 18717811268