Install the temperature sensor for optimum response and accuracy

Install the temperature sensor for optimum response and accuracy

Thermal sleeve length

To minimize the conduction error (heat loss error from tip to flange or joint along the sensor sheath or thermal sleeve wall), the immersion length shall be at least 10 times the diameter of the thermal sleeve or sensor sheath of the bare element. Therefore, for a thermowell with an outside diameter of 2.54 cm, the immersion length should be 25.4 cm.

For bare elements with a 6.35 mm outer diameter sensor sheath, the immersion length should be at least 63.5 mm. This is just a rule of thumb. The computer program can calculate the error and carry out fatigue analysis for various immersion lengths and process conditions. For high velocity flow and bare element installations, fatigue analysis is important because the probability of vibration failure increases with immersion length.

Thermowell location

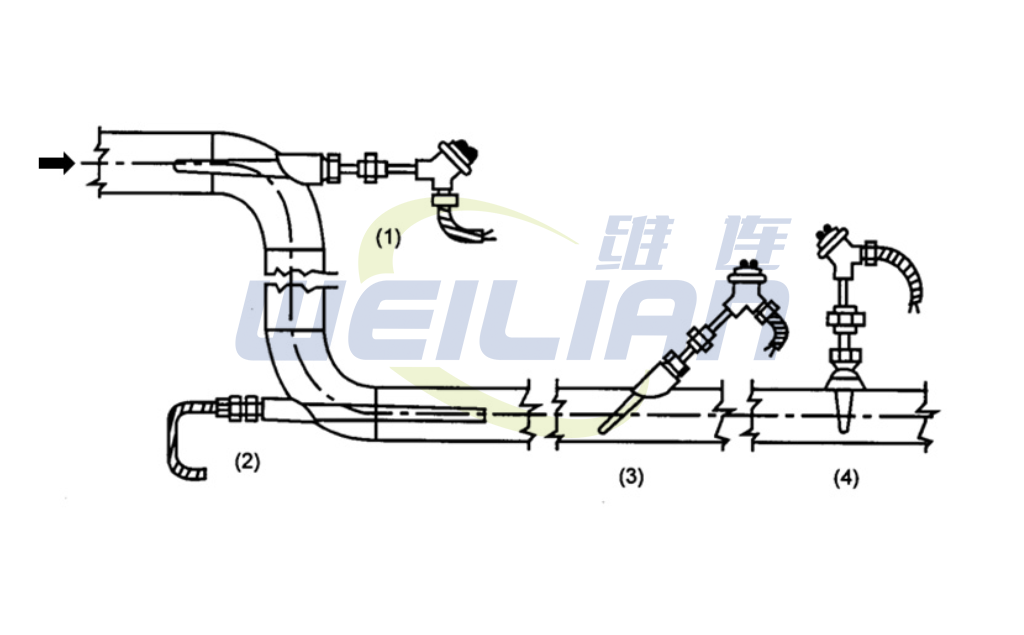

Due to imperfect mixing and wall effects, the process temperature will vary with the position of the process fluid in the vessel or pipe. For highly viscous fluids such as polymers and melts that flow in pipes and extruders, the fluid temperature near the wall may be significantly different from the fluid temperature at the centerline (for example, 10 to 30 ° C; 50 to 86 ° F). Typically, the diameter of special polymer pipes is less than 4 inches (101.6 mm), which leads to forgetting the problem of adequate immersion length and centerline temperature measurement. The best way to obtain representative centerline measurements is to insert the thermowell into the elbow facing the fluid (position 1 in the following figure).

If the thermal sleeve is facing away from the flow, rotated and separated from the elbow, it may produce more noisy and less representative measurement results (position 2 in the figure). Angular insertion (position 3 in the figure) can increase the immersion length of vertical insertion (position 4 in the figure), but the indicated insertion length is too short unless the tip extends beyond the centerline. Swaged or stepped thermowells can reduce immersion length requirements by reducing the diameter near the tip.

The distance between the thermowell in the pipeline and the outlet of the heat exchanger, static mixer or desuperheater shall be optimized to reduce the transport delay and minimize the noise caused by poor mixing or two-phase flow. In general, if there is single-phase turbulence and the viscosity of the mixed flow is not very different, 25 times the pipe diameter is enough to ensure full mixing from the turbulence.

There are two stages in the desuperheater, namely, the shunt transition from cooling water to steam in the jacket, and the use of lime ammonia as the pH control reagent caused by flash evaporation and whenever slurry is involved. The transmission delay will increase with the increase of distance, adding more dead time to the loop. Therefore, there is a tradeoff between obtaining sufficient mixing to achieve a representative low noise measurement and generating excessive additional dead time. In general, the transmission delay should be less than 10% of the PID reset time setting.

Note: In general, the distance of 25 times the pipe diameter between the equipment outlet and the temperature sensor is enough to provide a relatively uniform temperature distribution of single-phase fluid. The presence of different phases (such as bubbles or solids in liquids and droplets in vapors) and highly viscous fluids will require longer distances.

For desuperheaters, the distance from the outlet to the thermowell depends on the performance of the desuperheater, process conditions, and steam velocity. In order to feel this situation, there are some simple rules of thumb for the pipe length from the desuperheater to the first elbow (called the straight pipe length (SPL)) and the total pipe length from the desuperheater outlet to the sensor (called the total sensor length). Length (TSL).

The choice of thermowell length, location and structure determines whether the temperature measurement can represent the process, how much process noise is observed, how many delays and errors are introduced, and the potential failure rate. This article provides general guidance. For more details, including the equations used to predict the eight measurement error sources, see ISA Book Advanced Temperature Measurement and Control, Second Edition.

For bare elements with a 6.35 mm outer diameter sensor sheath, the immersion length should be at least 63.5 mm. This is just a rule of thumb. The computer program can calculate the error and carry out fatigue analysis for various immersion lengths and process conditions. For high velocity flow and bare element installations, fatigue analysis is important because the probability of vibration failure increases with immersion length.

The actual SPL and TSL values depend on the water volume required relative to the steam flow rate, temperature difference between water and steam, water temperature, pipe diameter, steam speed, model, type, etc., and are calculated by software programs SPL (ft)=inlet steam velocity (ft/s) x 0.1 (s residence time) SPL (m)=inlet steam velocity (m/s) x 0.1 (s residence time) TSL (ft)=inlet steam velocity (ft)/s) x 0.2 (s residence time) TSL (m)=typical value of inlet steam velocity (m/s) x 0.2 (s residence time). The range upstream of the superheater is 25 – 350 ft/s (7.6 to 107 m/s).

Below 25 ft/s, there is not enough power to keep water suspended in the steam stream. Water tends to fall out and run down pipes to sewers. When this happens, the water no longer cools the steam, and the system thinks it needs to add more water, which makes the problem more complicated. Problems may also include pipe wall corrosion and high thermal stress gradients in the pipe wall (i.e., hot at the top and cold at the bottom, which can crack the weld or warp the pipe into an egg shaped cross-section). The entry speed limit for current technology is 350 feet per second (107 meters per second). Speeds above 350 ft/s can cause the desuperheater to vibrate and damage the equipment to the point of rupture.

Thermowell structure

The stem of the thermowell is a component inserted into the process flow. Stems can be tapered, straight or stepped. The performance of the thermowell varies depending on the valve stem design. Typically, tapered or stepped stems provide faster response, produce less pressure drop, and are less susceptible to conduction errors and vibration failures. If the thickness of the thermowell wall and the fit of the sensing element are the same, thermowells with straight rods have the slowest time response because they have the most material at the tip (the largest diameter).

Thermowells with stepped stems have the fastest time response because they have the least material at the tip (smallest diameter). Small diameters also result in minimal resistance. The thermowell with stepped rods also provides the maximum separation between the wake frequency (vortex shedding) and the natural frequency (oscillation rate determined by the properties of the thermowell itself). If the wake frequency is 80% or more of the natural frequency of the thermowell, resonance may occur and damage may occur. Typically, thermowells with tapered rods are slightly more expensive due to more complex manufacturing processes.

Tip: swaged, stepped and tapered thermowells provide faster response, lower pressure drop and less possibility of vibration damage due to resonance with wake frequency.

The tip of the sensor must contact the bottom of the thermowell. Although installation practices and directions vary, the spring loaded sensor design helps ensure this. Since air acts as an insulator, the sensors should be fitted as closely as possible to reduce the annular gap. For sloppy fitting, the sensor hysteresis may increase by an order of magnitude. For liquid systems, the additional hysteresis actually becomes the additional equivalent dead time in the measurement.

Tip: The tip of the maintenance temperature sensor must contact the bottom of the thermal sleeve, and must be closely matched to prevent the introduction of large sensor hysteresis due to the low thermal conductivity of the air.

General guidelines on the insertion length, location, structure and fit of the thermowell are used to ensure that the sensor sees the actual process temperature, has low probability of vibration failure, and has minimum noise, delay and hysteresis.

Tel./WeChat 18717811268 Huang Gong Email sales@weilianchina.com