Mechanical temperature measuring sensor

Mechanical temperature measuring sensor

Temperature can be measured by various sensors. They infer temperature by sensing some changes in physical properties. There are four basic types of temperature measuring equipment, each using a different principle:

● Mechanical (liquid in glass thermometer, bimetallic sheet, bulb and capillary, pressure type, etc.)

● Heat junction (thermocouple)

● Thermal resistance (RTD temperature sensor and thermistor)

● Radiation (infrared and optical pyrometer)

Mechanical temperature measuring device

Operating principle

A change in temperature causes some mechanical movement, usually because most materials expand as the temperature rises. Mechanical thermometers can be constructed using liquids, solids, and even gases as temperature sensitive materials.

The mechanical movement is read on the physical scale to infer the temperature. Examples include:

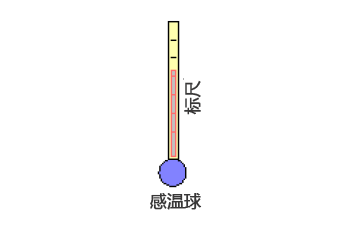

Liquid in glass thermometer

The most common and well-known thermometer is the liquid in glass thermometer.

The most common and well-known thermometer is the liquid in glass thermometer.

Bimetallic thermometer

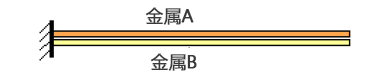

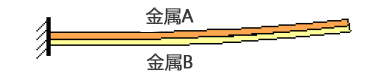

As shown in the figure below, two different metals are combined to form a so-called bimetallic strip.

It is assumed that the coefficient of thermal expansion of metal A is less than that of metal B. As the temperature rises, metal B expands more than metal A, causing the bimetallic strip to curl up as shown in the figure.

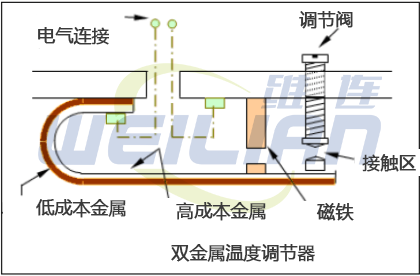

A common application of bimetallic sheets is air conditioning thermostats, where bimetallic sheets are used as switch arms between electrical contacts. As the room temperature changes, the bimetallic strip will bend as described above. When the bimetallic strip is bent far enough, it will contact the electric wire to turn on or off the heating or air conditioning.

Another common application is as an oven thermometer or wood burner thermometer. These thermometers consist of coiled bimetallic strips connected to a dial which is calibrated as a temperature scale.

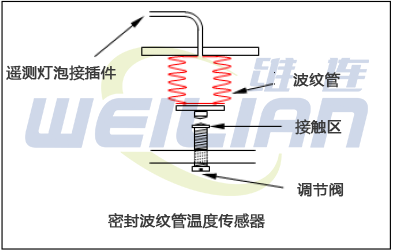

Sealing bellows

The sealed bellows type is filled with gas, steam or liquid, and responds to temperature changes by causing expansion or contraction due to changes in volume and pressure.

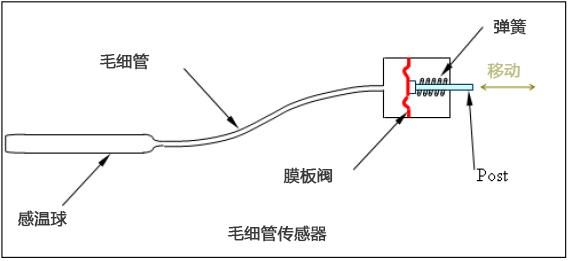

Bulb and capillary sensor

Bulbs and capillary elements are used to measure temperature in pipes, tubes, cans, or similar locations away from the controller.

The bulb is filled with liquid, gas or refrigerant depending on the desired temperature range. The expansion of the fluid in the heating ball exerts pressure, which is transferred from the capillary to the diaphragm where it is converted into motion.

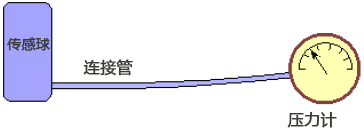

Pressure thermometer

Although still considered mechanical, pressure thermometers work by expanding gases rather than liquids or solids. (Note: There are also pressure thermometers that use liquid instead of gas.)

It is assumed that the gas in the bulb and tube can be considered as ideal gas.

The ideal gas law is PV=m RT

P is the pressure,

V is the volume of the gas,

M is the mass of the gas,

R is the gas constant of a specific gas (not the general gas constant), and

T is the absolute temperature of the gas.

The volume of bulb and tube is constant, so V is a constant. In addition, the mass m of the gas in the sealed bulb and tube must be constant. Therefore, the above equation is simplified to P=kT, where k is a constant.

Therefore, pressure thermometers measure temperature indirectly by measuring pressure. The instrument is a pressure gauge, but is usually calibrated in temperature units.

A common application of this type of thermometer is to measure the external temperature from inside the building. The bulb is placed outside, and the tube goes through the wall and into it. The meter is inside. As the external T increases, the bulb temperature causes a corresponding increase in pressure, which is read on the gauge as an increase in temperature.