What is the thermowell and how to select the thermowell probe length?

The International Society for Testing and Materials (ASTM) defines the term T thermowell as "a device designed to insert a closed end recessed tube into a temperature sensing element and provide a pressure seal connection to the vessel".

A thermal sleeve is a hollow tube with one end closed and the other end threaded. They are permanently placed in pipes, tanks or catch basins so that temperature measuring probes can be inserted into the pipes to measure the temperature of the contents. It is also a housing that protects the temperature sensor probe (RTD or thermocouple) from exposure to hazardous materials or extreme environments.

Material: It is made of forged bar/pipe. The thermal sleeve includes carbon steel (A105), SS304, SS304L, SS310, SS316, SS316L, SS446, SS410, SS317, SS317L, SS321, nickel, Hastelloy, etc,

The choice of the thermowell material depends on the process conditions, such as the corrosive liquid being measured. Teflon can be used for low pressure and low temperature applications.

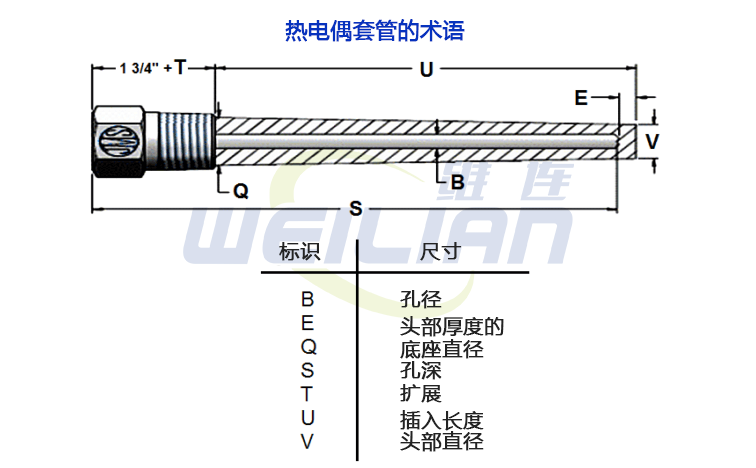

Basic components of thermowell

Hole diameter (B):

This is the inner diameter of the thermowell.

Drilling depth (S):

The total length of the hole.

Insertion length:

The immersion length of the thermowell is commonly referred to as the "U" length, which is a measurement of the thermowell from the bottom of the process connection to the top of the thermowell.

Process connection:

This is how the thermowell is inserted and connected to the process associated with connecting the element. The most popular are threaded, socket welded and flanged connections.

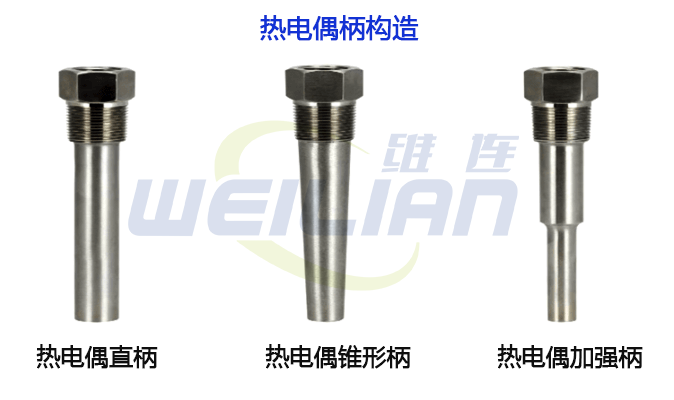

Handle structure:

This is the immersed part (handle) of the structure. Most fall into three categories: linear, stepped, or tapered.

● The straight shank has the same size over the entire immersion length. For general use, use straight shanks or rods where no additional strength is required.

● In some applications, the step shank has a larger outside diameter at the end of the immersion length to speed up response time.

● The tapered version gradually decreases along the immersion length. Conical thermowells are designed for high-speed use where additional strength is required. Special attention shall be paid to the vibration effects caused by the fluid passing through the thermal sleeve.

6. Extension length of rubber coating (T):

The lagging extension, commonly referred to as the "T" length, is located on the cold side of the process connection, usually an extension of the hexagonal length.

7. Base diameter dimension (Q):

This is the external dimension of the thermowell handle and the part with the highest density, because the outer surface area is exposed to harmful materials in the process.

8. Tip thickness (E):

The thickness of the bottom of the thermowell.

9. Tip diameter (V):

Diameter of thermowell end.

Type of thermowell

Threaded thermowell

They are used in smaller pipes to measure the temperature of non corrosive fluids and to screw thermowells into the pipes.

Flange type thermal sleeve

The flange top of the flanged thermocouple temperature sensor sleeve is connected to the pipe with nuts and bolts. The thermowell has a flange collar which is attached to the coupling flange. Use this type of thermowell when frequent replacement or disassembly is required.

Flanged thermowells are used for high temperature applications.

Welded thermal sleeve

The welded thermowell is welded directly into the pipe. Since the thermal sleeve is welded into the pipe, it is used for permanent connection.

Probe length of thermowell

The tip of the temperature sensor must contact the bottom of the thermowell. The temperature sensor (such as thermometer, thermocouple or RTD) is inserted into the open end of the thermowell, usually spring loaded, to ensure that the outer tip of the temperature sensor and the inner tip of the thermowell are in metal to metal contact. Since air acts as an insulator, the sensors should be fitted as closely as possible to reduce the annular gap.

There is no standard procedure for selecting the probe length relative to the thermowell. The thermowell has different lengths according to different standards, and sensor probes such as thermometers, RTDs, and thermocouples have different sizes. The appropriate probe length must be selected according to the thermowell.

For example, in some cases, if the probe length is smaller than the thermocouple, high boiling oil can be put into the thermowell to transfer heat to the probe. It is in a low priority measurement. It all depends on the application of the measurement.

In another case, if the probe is too long, the rod outside the thermowell will bend and may cause physical damage.