Protecting NTC Thermoltage resistance temperature sensor is not a common method that can be used to encapsulate or encapsulate them in epoxy resin. The chemical characteristics used to protect NTC thermistor are existing in industrial -grade epoxy resins with high -agency strength and thermal conductivity.

The NTC thermistor temperature sensor with epoxy resin is manifested as tear -shaped beads with two radial leads. These types of NTC thermistor temperature sensors are usually used to approach the application of humidity. Some of these applications include medical equipment that measures air flow and air temperature. Epoxy resin bead -shaped thermistor is often used in the automotive industry to monitor the air conditioning and seat heating of the cab.

Green energy such as wind turbines will encounter potential destruction under the cold climate. Ice rain or lower than the freezing point will cause the leaves to freeze, resulting in a decrease in power output and increased rotor load. NTC thermistor temperature sensor probe monitoring and controlling the temperature of the blades to allow the turbine to control the fast -opening/off control rapid response.

It is essential to prevent NTC heat -sensitive resistance directly contacting fluids (such as water or oil). To this end, the use of heat conduction epoxy resin is used as a sealing agent, called "sealing", and the NTC thermistor temperature sensor is sealed in the stainless steel shell. This epoxy resin can not only protect the NTC sensor from moisture, but also achieve good thermal conduction from the measuring medium to the thermistor sensor. Thermal conductive epoxy resin can provide operating efficiency without degradation.

Stainless steel sensor probes are used in the automotive industry that can measure the engine, oil level and viscosity of oil temperature vehicles, and the temperature of the cooling agent of the engine. Another NTC thermistor that is encapsulated in the probe component is a ring -shaped tie probe. The thermal resistance component is used to measure the surface temperature.

Circular wire thermistor temperature sensor probe probe is usually installed on the radiator to measure the working temperature of the power component. They are also increasingly used for lithium -ion battery terminals to monitor battery temperature during charging and discharge cycle to improve efficiency and safety.

|

|

|

|

|

|

|

|

Tin -plated metal ring ear |

Stainless Steel 304 threaded tip and hexagonal head |

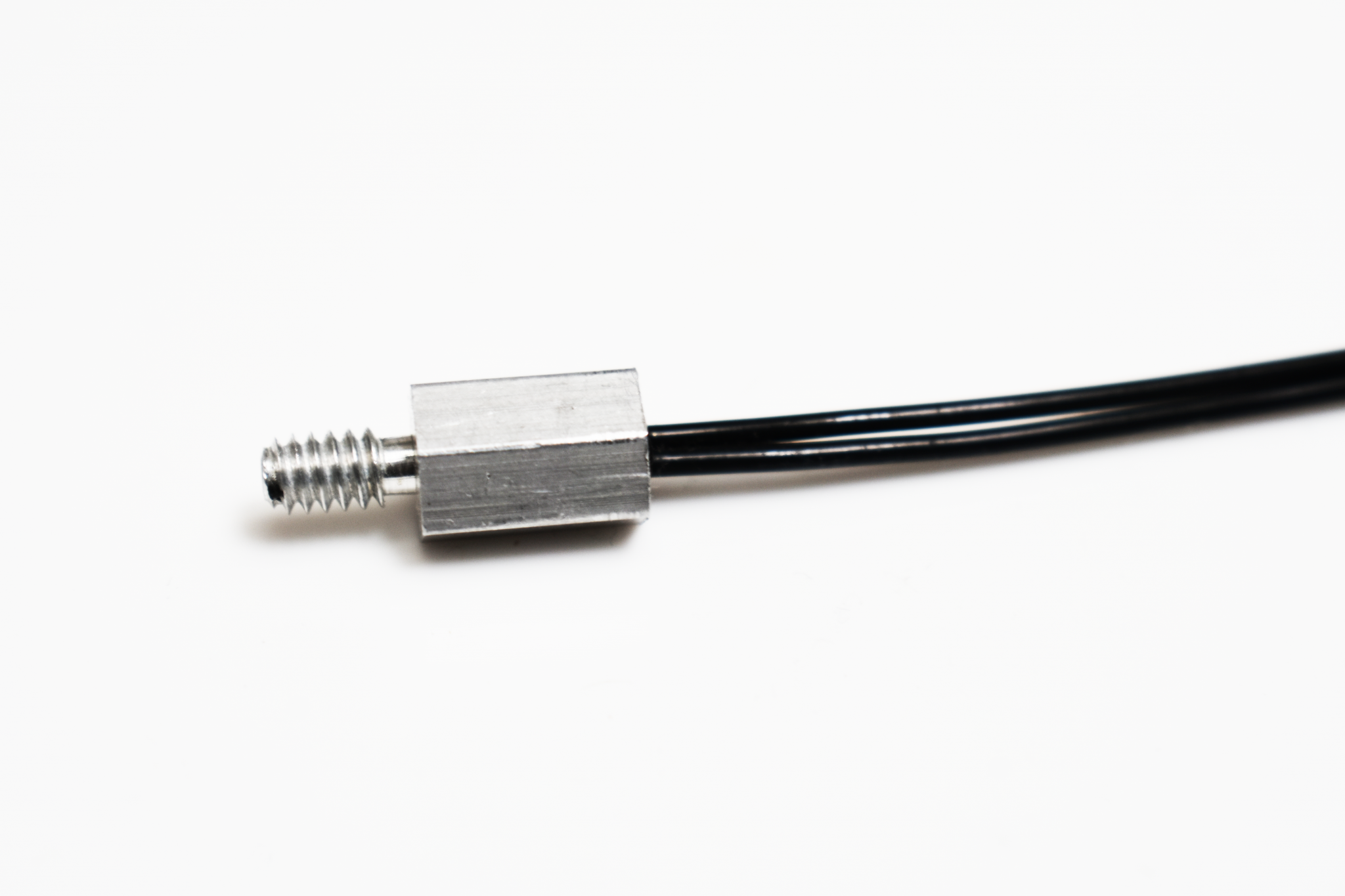

Aluminum thread metal tube and hexagonal clock |

probe component with epoxy resin |

Stainless Steel 304 closed metal tube |

Glass marble |

| Detection |

TRR |

TRT |

trw |

TRE |

TRH |

TRG |

| Hot Time constant (s) |

40 |

40 |

25 |

10 |

10 |

3 |

| Disopular constant (MW/° C) |

3 |

3 |

10 |

3 |

3 |

3 |

| Maximum power (MW) |

125 |

125 |

125 |

125 |

125 |

125 |

| House type |

Tin -plated metal ring ear |

Stainless Steel 304 threaded tip and hexagonal head |

Aluminum thread metal tube and hexagonal clock |

probe component with epoxy resin |

Stainless Steel 304 closed metal tube |

Glass marble |

| Probe Description |

Epoxy resin immersed NTC thermistor resistance packaging In the tin -plated copper ring wiring sheet |

NTC thermistor is sealed in an aluminum hexagonal screw, straight thread |

NTC thermistor is packaged at the tip of durable stainless steel, allowing pipes to have a tapered thread hexagon screw |

Epoxy resin immersed NTC thermistor -sensitive resistance on the TEFLON/PVC wires with a cover |

NTC thermistor and epoxy resin filling in durable stainless steel alloy tubes |

Glass packaging bead -shaped thermal resistance with Teflon coating wire |

Four reasons for sealing epoxy resin

1. The moisture -proof protection of thermal resistance

Epoxy resin coating or sealing provides moisture -proof barriers to prevent water vapor from invading thermoltic resistance sensors. This helps to obtain level 1 humidity sensitivity (MSL 1) level, which indicates that thermal resistance can avoid water penetration in an infinite period of time.

Wet sensitivity level

| Category |

Allow time |

| MSL 1 |

Unlimited, not sensitive |

| MSL 2 |

1 year |

| MSL 2A |

4 weeks |

| MSL 3 |

1 week |

| MSL 4 |

3 days |

| MSL 5 |

2 days |

| MSL 5A |

1 Day |

| MSL 6 |

You must bake |

2. The physical protection of thermal resistance

Sealing NTC thermal resistance with epoxy resin can protect the sensor from accidental impact during manufacturing and operation. Without this protection, the impact may cause the key tolerance of the thermistor to lose the long -term accuracy. Epoxy resin coating or sealing can also provide effective protection in the application of high -energy or high -frequency vibrations in the application of high -energy or high -frequency vibrations, such as applications related to mining equipment, industrial vehicles and aircraft.

3. The electrical insulation of thermistor

The type of

epoxy resin is used for sealing and coating NTC thermistor can also be protected in the form of electrical insulation. The accidental electrical contact with other components, metal cases or chassis parts may damage thermistor. Epoxy resin coating can also prevent oxidation on the surface of thermistor.

4. Flame retardant and flame retardant thermistor

Epoxy coating is both flame retardant and flame retardant. This important feature of industrial -grade epoxy resin originated from additives in epoxy resin coatings, which helps the overall safety of the product.

Use epoxy resin to protect NTC thermistor temperature sensor

Use epoxy resin to protect NTC thermistor temperature sensor