What is PTC thermal resistance ?

What is PTC thermal resistance ?

PTC represents "Zheng temperature coefficient ". PTC thermistor is a resistor with a positive temperature coefficient , which means that the resistance increases as the temperature increases.

PTC thermistor is divided into two groups based on the materials, structure and manufacturing process used. The first group of PTC thermistor is composed of silicon resistance, which uses silicon as semiconductor material. Because of their linear characteristics, they are used as PTC temperature sensors .

The second group is the heating resistance of the switch -type PTC. The switch-type PTC thermistor has a highly non-linear resistance-temperature curve. When the thermistor of the switch -type PTC is hot, the resistance starts to decrease first until it reaches a critical temperature. As the temperature rises to the critical value, the resistance increases sharply. This type of PTC thermistor is widely used in PTC heater, sensors, etc. The polymer PTC thermistor is made of special plastic, which belongs to the second category and is usually used as a self -recovery fuse.

PTC thermistor definition

PTC thermistor is a thermistor, which increases significantly with the temperature increased by the temperature.

PTC thermistor characteristics

The silicon wafer has a linear resistance-temperature characteristics, and its slope is relatively small in most of its working range. They may show negative temperature coefficients at temperatures higher than 150 ° C. The resistance temperature coefficient < / u> of the silicon wafer is about 0.7 to 0.8% / ° C.

The thermistor of the switch PTC is usually made of polycrystalline ceramic materials. These materials have high resistors in their original state and are semi -conductive by adding doping agents. They are mainly used as PTC self -regulating heater. The transition temperature of most switch -type PTC thermistor is between 60 and 120 ° C. However, the manufactured special application equipment can be switched at a temperature of as low as 0 ° C or up to 200 ° C.

Change temperature (t C)

It can be seen from the figure that the switching PTC thermistor has a slightly negative temperature coefficient before the resistance of the resistance. On this point, it experienced a slightly positive coefficient before reaching its transformation temperature (T C). The temperature is sometimes called the switch temperature or the temperature. The switching temperature is the temperature where the resistance of the switch -type PTC thermistor starts to rise rapidly. In most cases, the temperature is defined as the temperature when the resistance value is twice the minimum resistance value.

minimum resistance (R min)

The minimum resistance of the PTC thermistor is the minimum resistance that can be measured on the switch -type PTC thermistor, as shown in the RT curve. It is the point that the temperature coefficient on the curve becomes a positive value.

Rated resistor (R 25)

The rated PTC resistance is usually defined as a resistance at 25 ° C. It is used to classify thermistor according to the resistance value. It is measured with low current, and the current does not hear thermistor to the degree of measurement.

Disposal constant

The relationship between dissipation constant represents the relationship between the applied power and the increased body temperature caused by self -heating. Some factors affecting the dissipated constant include: contact line materials, the installation method of thermal resistance, the environmental temperature, the transmission path between the equipment and the surrounding environment, or the size and even shape of the equipment itself. The dissipation constant has a significant impact on the self -heating characteristics of thermistor.

Maximum rated current

The rated current indicates that under the specified environmental conditions, the maximum current of the PTC thermistor can be continuously flowing. Its value depends on the dissipation constant and the RT curve. If the thermistor is overloaded to the point where the temperature coefficient starts to decrease again, this will cause the out of control's power supply and damage to the thermistor.

Maximum voltage

Similar to the maximum rated current, the maximum rated voltage represents the maximum voltage of the thermistor resistance under the specified environmental conditions. Its value also depends on the constant and RT curve.

Operation mode

According to the application, PTC thermistor can be used for two operation modes; self -heating and induction (also known as zero power).

Self -heating mode

The self -heating application uses such a fact, that is, when the voltage is applied to the thermistor and a sufficient current flows through it, the temperature will rise. When the temperature is close to the temperature, the resistance increases sharply, and the current flows are much less. This behavior can be seen from the left picture. Within a few degrees of temperature, the resistance changes near the temperature can be several magnitude. If the voltage is kept constant, the current will stabilize to a certain value when the thermistor reaches the thermal balance. The balance temperature depends on the exerted voltage and the heat dispersion factor of the thermistor. This operation mode is often used when the design temperature -related time is delayed.

sensing (zero power consumption) mode

In this operation mode, the power consumption of thermistor is very small. Compared with the self -heating mode, it can ignore the temperature and resistance of the thermistor. The sensor mode is usually used to measure the temperature with the RT curve as the reference.

Architecture and Property

Silicon wafers depend on the body's doped body characteristics and show a linear resistance-temperature characteristics. They are made of high -purity silicon wafers and make different shapes. Temperature-resistance curve depends on the doped amount used.

Switch PTC thermistor is made of polycrystalline material. They usually use mixtures of additives such as carbonate, titanium oxide and crickets, silicon and manganese. The material is grinded, mixed, compressed into a disc or rectangular shape and sintering. Then, add the contact and coat or package it. The manufacturing process needs to control the materials and impurities very carefully. The pollution of millions of thousands of inch can cause major changes in heat and electrical properties.

The polymer PTC is made of a piece of plastic, which is embedded in carbon particles. When the device is cooled, carbon particles are tightly contacting each other to form a conductive pathway through the device. As the equipment is heating up, the plastic expands, and the particles are further separated, thereby increasing the total resistance of the equipment.

Typical Application of PTC thermistor

Self -adjusting heater

If the current flows through the switch PTC thermistor, it will automatically stabilize at a certain temperature. This means that if the temperature is reduced, the resistance will also be reduced, which allows more current flow to heat the device. Similarly, if the temperature rises, the resistance will increase, thereby limiting the current of the device to cool the device. Then, the PTC thermistor reaches such a point, that is, within a relatively wide voltage range, the consumption power is actually not related to the voltage. These PTC thermal resistances are usually made of ceramics of various shapes and sizes, and due to their design flexibility, the PTC ceramic heater is an excellent choice for controlling controlling electrical heating. To increase heat transfer, ceramic heating elements can be installed on aluminum radiators or grilles. There is also a printed PTC heater ink, which can be printed on the screen to the polymer substrate to manufacture the PTC heater.

Polymer PTC fuse

Overcurrent Protection

The switch PTC thermistor is used as an overcurrent limiter or a self -recovery fuse in various circuits. In the case of overcurrent, the temperature of thermistor rises and rapidly reaches the transition temperature. This has led to the sharp rise in the resistance of the PTC thermistor, which limits the current in the circuit. When the current or short circuit is resolved, the circuit will return to normal work after the thermistor is cooled again. In this way, it acts as automatic self -recovery fuse. The heating resistance of polymer PTC is usually used here. They are known for different commodities, such as Polyfuse, Polyswitch, and Multifuse.

Time delay

It can be used to use PTC thermistor to be heated to the time delays in the circuit that can be switched from low resistance state to high resistance state, and vice versa. Delay depends on the size, environmental temperature and the voltage it connected, and the circuit it uses. An example of PTC thermistor delay is their use in fluorescent lamps. When the first power is powered on, the thermistor is cold (room temperature). The lamp voltage is lower than the ignition voltage, and the current flowing through the circuit at the same time heater and PTC. When the temperature is reached, the PTC will be switched, the voltage at both ends of the lights will exceed the ignition voltage, and the light will start working normally.

motor startup

Some motors have a separate start -up winding, which only need to be powered during the motor startup. In this case, the self -heating effect of the PTC thermistor can be used in series with this winding. When the circuit is turned on, the PTC thermist resistance has a low resistance value, and the allowable current can pass through the starting winding. When the motor starts, the PTC heat -sensitive resistance rises and switch to a high resistance state at a certain moment. The time required for this situation is calculated based on the required motor startup time. Once heated, the current of the PTC thermistor can be ignored, which will cut off the starting winding current.

Substances

These applications depend on changes in the frequency of dispersing constant during transmission and heat transmission. The increase in the dissipation constant caused by the increase in air flow or the increase in air flow on the device or the increase in air flow on the device will reduce the working temperature of the thermistor resistance and increase the power volume required to maintain the given body temperature. You can measure the power increase and indicate the thermist resistance for the system such as immersion in the liquid.

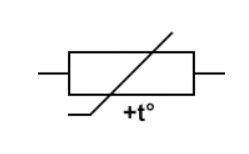

PTC thermal resistance symbol

According to the IEC standard, the following symbols are used for the thermistor of the positive temperature coefficient.

PTC thermal resistance symbol (IEC standard)